Sidwin Fabric (P) Ltd. is one of the leading manufacturers, suppliers and exporters of PP spun bond nonwoven fabric since 2011. “Over these 10 years we have gained exceptional insights into the products of nonwoven, giving us an edge over the competition. We are known for products manufactured from high-quality raw material. Sidwin Fabric is a name that reckons with integrity and transparency. The group companies of Sidwin Fabric are Airolam Decorative Laminates and Signova Tiles,” informs Suresh Patel, Managing Director.

Strong Infrastructure Focus

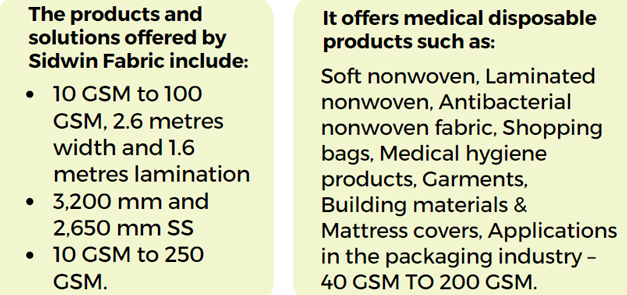

Giving an overview of the company’s manufacturing infrastructure, recent investments and capacity, Suresh Patel mentions that the premises of Sidwin Fabric cover around 80,000 sq. metres installed with the latest technology and complete automatic machinery with a capacity of 1,000 MT per month. He further adds, “The latest installed machinery is India’s first four beam SSMS fully automated with a high-end quality. This plant is designed explicitly for hygiene industries like baby diapers, sanitary napkins, adult diapers and medical healthcare products that require the highest level of hygiene.”

“The most significant advantage that Sidwin Fabric has and continues to focus on is the quality of the product. We make sure that the clients are 100 per cent contented with the kind of quality and service that we provide. Our primary focus is also making sure the product is manufactured and delivered on time,” he adds. When queried on the breakup of the company’s business between the domestic and export markets, Patel replies: “Sidwin Fabric has been a late entrant in the nonwoven fabric business; however, that helped us focus on the export markets for the last seven years. Today we can boast that we export 60% of the fabric directly or indirectly to countries like the USA, Canada, and UAE, just to name a few.”

“On the domestic side, we focus on clients seeking quality products, as we manufacture 100% virgin grade fabric. We focus on customised products as the end-use varies from client to client,” he further states. Listing down the competitive edge and the advantages it offers to customers, he points out: “Clients have been very particular about the kind of material that is required for their business; if they do well, we do well. Clients want quality and most of them expect to have certifications that are approved by various bodies across the globe. Take for example the OEKO-TEX® from Germany which is acceptable across the globe and we are the first organisation in India to have such a certification.”

“We go to any lengths to fulfil the expectation of the clients be it in terms of product or the service that the clients would need. We have made sure that the client gets quality products appropriately. We have also made sure we take utmost care within the operations area to maintain hygiene and keep the plant dust-free. The biggest strength of our organisation is that we have a robust system. We always update ourselves with the latest in technical textile manufacturing. Our new plant is being set up in SSMS, India’s first four beam plant and we should start production soon. We are always ready to try out new technologies and take calculated risks wherever necessary,” he adds.

“Currently, more than 150 workers work with us, and the number, however, is gradually increasing as we are expanding our company’s capacity,” he replies to a question on Sidwin Fabric’s team strength. Throwing light on the company’s sustainability focus, Patel mentions that Sidwin Fabric is India’s first company in the MSME sector that is shifting to complete solar and wind energy for the entire manufacturing plant and office. Replying to a question on how the company is adopting automation and Industry 4.0 in its manufacturing process, he responds: “We at Sidwin Fabric adopted fully automated machinery for all the manufacturing units from the initial days. As time passed by, we gradually modified the machinery and got in the new generation of automated high-end quality machines for the best outputs. We have considered Industry 4.0; however, we currently do not need robotics, artificial intelligence or machine learning for our products.”

Ambitious Growth Plans

Finally, going into details regarding the company’s future growth plans and its vision for 2025 and beyond, he says: “We recently expanded with an SSMS line, India’s first four beam plant with 350 MT capacity specifically for the hygiene industry. We also specialise in the agriculture crop protective cover and recently procured converting equipment for many products. In the year 2020 the company installed a 1 MW solar generation plant and 2 MW windmill for electricity generation for the entire plant and office; this will reduce the dependency on the grid and help us become self-reliant and sustainable. Sidwin Fabric has a target of achieving more than Rs 300 crore in terms of turnover while further expanding the production capacity,” he adds, on a parting note.