In a bid to actively help the German government, Innovatec and Oerlikon Nonwoven are working towards facilitating the production of protective gear such as face masks since the demand for them has increased.

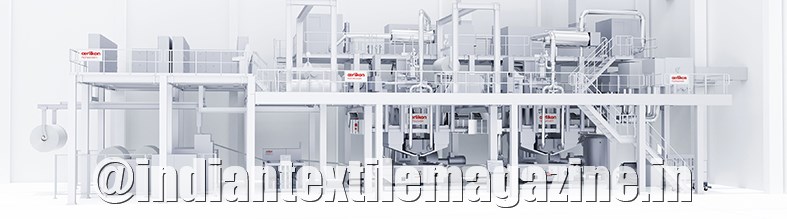

In alignment with the development, Innovatec has commissioned 2nd meltblown system by Oerlikon Nonwoven at the former’s state-of-the-art machine park in North Rhine-Westphalia. Innovatec has begun producing polypropylene filter nonwovens almost instantly. The domestic manufacturer is being supported by the German government.

The 1st Oerlikon Nonwoven was delivered to Innovatec in June 2020 which was a 2-beam system, according to Rainer Straub – Head, Oerlikon Nonwoven.

With the addition now, the company has managed to almost double its filter nonwoven output. It can now manufacture up to 2.5 billion operating room filter masks or a billion highly-effective FFP2 masks in a year.

Innovatec is part of the German government’s ‘Nonwovens Production’ grant programme to ramp up its output capacities. The industry and the government together want to ensure that the production capacities for protective equipment continue to grow in Germany and that the critical supply chains are secured at both national and European levels.