2022 is promising to become a very special year in the long and extraordinary history of Terrot. Not only the company celebrates its 160th anniversary, it is also expecting to produce more machines under Terrot and the recently incorporated Pilotelli brand, at its headquarter in Chemnitz, Saxony as at any time before. After a severe crisis in 2019/2020 amplified by an early hit of the Covid-19 pandemic the 50% growth in 2021 is looking to be repeated once more in the current year, with a confident volume of 260 new orders alone in the first quarter. Combined with the order inflow from 2021 this not only utilizes a large portion of our annual production capacities for this but also a significant amount for 2023.

Whereas 2020 was dominated by single jersey machines, the last year was mainly characterised by high demand in home textiles, mattresses and the sportswear sector, for both mechanical and electronical machines. It is important to point out, that all this has been achieved despite still lasting problems with supply chains leading to delays, sky rocketing prices for commodities, raw materials and parts, in particular electronic like semiconductors, as well as transportation that stretched us as probably many others to the breaking point. All this would not have been possible without our staff that invests everyday all their passion in catering for the needs of our sophisticated clients and of course healthy economy that accompanies us since the last almost two years. But most of all we would like to thank world’s leading textile companies and garment producers who put trust in the highest quality, productivity and flexibility of our machines. We very much value the partnerships that have evolved out of client supplier relations over the years and decades.

Despite the uncertainties deriving from the war in Ukraine and continuous price increases, in particular for energy, yarns and transportation until now the demand remains stable and the general sentiment is still positive. Given a hopefully peaceful negotiation solution between Moscow and Kyiv we expect the growth trend to remain stable for a while. A continuous increase in demand for premium machines as well as an ongoing transformation processes in the textile sector, characterized by a growing share of knitted fabrics, digitization and sustainability issues enable us to develop from a machine manufacturer into a comprehensive solution providing partner to our existing and future customers.

From standardized machines for serial requirements to highly customized for special designs and structures, we therefore offer the widest range of machine types for high-quality knitted fabrics in a variety of gauges and realize a truly flexible customer-centric approach. Moreover our machines easily fit into smart factories by providing a fully interoperable “network user interface”. A remote service possibility and a newly developed trouble shooting assistance software mark our progress into the digitised era. Terrot is successfully selling machines into more than 100 countries around the world.

A network of over 50 qualified sales agencies guarantees the close contact to the customers and supports them by servicing on the existing as well as implementing and installing new machines and responding to their spare part needs. Our main markets are India, Uzbekistan and Turkey. But we also distribute a large quantity of machines to Europe, Asia and Latin America which guarantees a well-balanced sales performance and avoids cluster risks.

The past year has seen also changes in the shareholding structure of the company with the managing directors, Mr Robert Czajkowski as the CEO, and Mr Dirk Lange, who joined Terrot in 2020 moving up to becoming managing partners, not only ensuring continuity for the years to come but also emphasizing the owner-managed tradition of this German machine manufacturer.

New developments in the single and double jersey sector, consisting of premium high efficiency machines with outstanding performance, maintenance and operating cost KPI’s as well as general improvements on our existing equipment are on the way. With new investments in machinery, software and process optimisation in the production and the set-up of a new R&D entity that is aiming to serve as an agile hub for co-operations with innovative companies and research institutes around the world. By this we are looking forward to exploring new developments in areas of robotics, environmental technologies or textile software we are embracing limitless opportunities lying ahead of us. With our clients we aim to explore the new horizons that this industry offers in the decades to come.

knit-tech Review

We were very much looking forward to presenting the finest German engineering – genuinely “Made by Terrot” circular knitting machine as well as the wide range of our Terrot services: After pausing for 3 years the knit-tech trade fair, as the leading textile exhibition in southern India, has taken place again in Tirupur from June 3rd – June 6th, 2022. The 16th edition of knit-tech was very successful for Terrot: The number of visitors and the interest shown by customers, professional visitors and business partners were simply overwhelming.

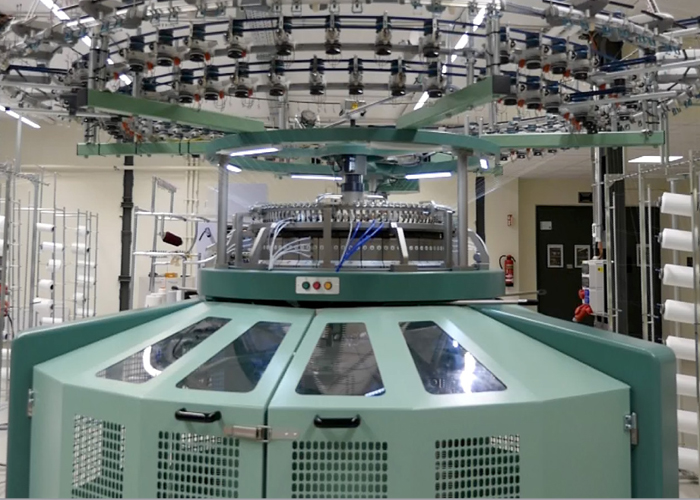

With our partner Voltas we exhibited a highly flexible and productive machine that has been much demanded globally in the past years and after being tested in India by reputable clients of ours is much likely to become also a success story in your market:

I3P 584, diameter 34“ in gauge 18

Our state of the art Terrot fine rib machine model has become the main attraction at our booth.

The great enthusiasm at our booth of our visitors and their feedback about among others the output of 650kg (100% cotton fine rib production per day) was extremely positive.

The 8-lock machine I3P 584 is an all-rounder and creates typical 8-lock structures like interlock, punto di roma, milano rib and piqué rodier in a high quality.

I3P 584 – advantages at a glance

• Made in Germany – maximum efficiency and precision

• 2.8 feeds per inch and a maximum speedfactor of 1,050 guarantee a high output

• Precise adjustment of delayed or synchronized timing with an impressive timing delay up to 5 mm for dimensionally stable and durable fabrics

• Great flexibility and large pattern range with up to 4 needle tracks in cylinder and 2 needle tracks in dial cam

• High quality elastane plating in all variations

• Use of easily accessible and cost-effective needles

• Well-equipped for different market requirements with different conversion kits for spacer and fine gauge fabrics

• Quick and easy gauge exchange with minimal effort

The presentation of the Pilotelli machine JV-3.0 with a max. speed factor of 1,500 was the second highlight.

160 years of experience and progressive thinking is resulting in a single-jersey machine with highest productivity at a maximum of 45 rpm at 32 inch with Open Width take down.

All the well-known and standard setting Pilotelli features like Click-Clack, reliable elastane plating and perfect handling under harsh industrial conditions characterize our latest machine model, too.

Three feeders per inch and high speed guarantee a minimum spirality of fabric by maximum production output. Furthermore we have developed and approved a new cam design embodying a revolutionary approach: The design allows highest speed with lowest needle wear and extended cleaning intervals. Up to 100 tons per needle set a new benchmark in this segment.

A much longer cleaning cycle compared to our main competitors and therefore higher productivity are some of the main benefits. Furthermore the machine is able to produce the known structures like piqué and 2-thread fleece.

A special yarn carrier with 4-hole design gives the user the possibility to produce plated single jersey and fleece without changing settings and parts. This guarantees reliable handling and best fabric quality.

The general sentiment of the market was particularly positive. The demand for technologically advanced and high-quality circular knitting machines remains high.

The personal encounters and valuable discussions at the trade fair showed first fruitful effects resulting in large quantity of deals and concrete inquiries. India is one of the leading, highly professional and most dynamic textile markets around the globe. The pleasant, top technology seeking and innovation minded atmosphere at the knit-tech will furthermore be a motor of motivation for our thrive for excellence and driving force for the entire industry. We will certainly be back on the next possible occasion.