Be it manufacturing protective gear for the armed forces, and performance sportswear for sportsmen, laminated luggage fabric or high-density PVC coated industrial fabrics – the market is pulsing with the name Nobletex which has created a niche for itself in these segments. Team WOTT speaks with Paresh Choudhary, Managing Director – Nobletex Industries in an exclusive interview and understands the company’s strategies, future road map and what makes it a preferred partner.

Nobletex Industries specializes in advanced technical textile solutions and manufactures high-end specialty fabrics. This 40-year-old company, part of Pratibha Group of Companies, offers a range of fabrics that are PU and PVC coated, EVA foam laminated and interlining ones, besides other technical fabrics.

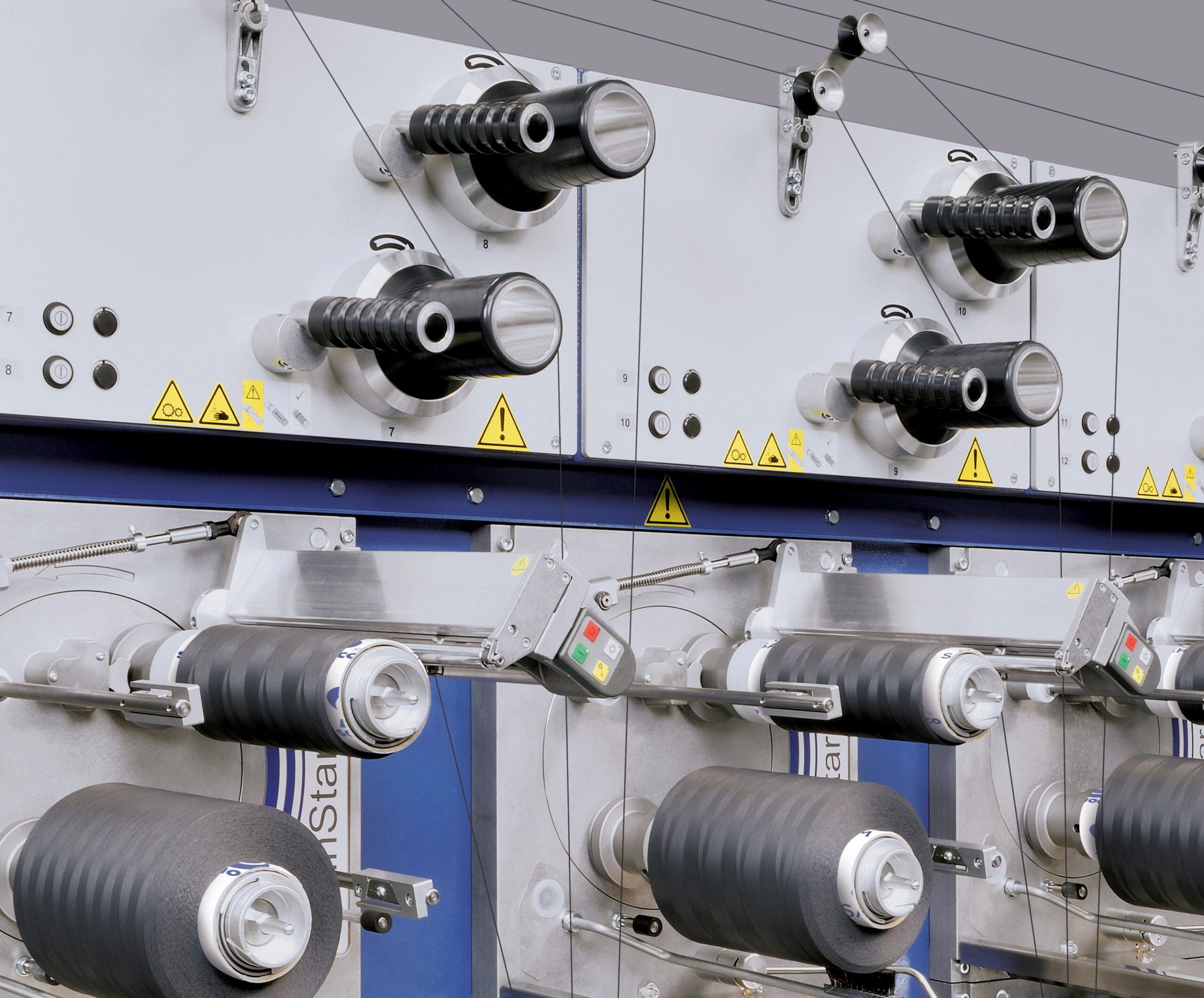

Located 20 kms from Surat, Gujarat, Nobletex has invested in state-of-the-art facilities equipped with yarn spinning, weaving, dyeing and finishing, coating, fabrication and material testing facilities, with a production capacity of 10 million meters per annum.

The company also efficiently manages the complete industrial chain – right from the yarn to the finished product.

Excerpts from the interview:

Nobletex Motto

The company is dedicated to eliminate wasteful consumption of unnecessary raw materials, processes, and energy. It works steadfastly towards lowering the quantities of waste created during the production process. Nobletex follows the principle of – Avoid, Reduce, Recycle.

Preferred Partners in Success

Nobletex offers highly technical and specific requirements of its discerning clients and efficiently manages end-to-end industrial chain. This helps the company to maintain consistent quality and uphold excellent lead times. Scalability of manufacturing is another key differentiator of Nobletex – be it small or huge quantities and standard or tailor-made products. The company boasts of its own R&D division and fully supports new and innovative ideas and products. Offering its customers superior quality and value for money that translates into a competitive edge for them is what sets Nobletex apart from competition.

Consistently Innovative

The in-house product development division at Nobletex is highly agile creating innovative solutions. The idea is to develop products that are economic and ecological because the core members believe that ‘fabrics should perform beyond their basic functionality’.

Equipped with latest testing machines, the laboratories and the facilities at Nobletex are capable of conducting trial iterations with a sample loom, dyeing machines, lab coater and padder at their disposal.

Nobletex is proud of its recent research innovations in luggage and defense fabrics and personal protective clothing categories.

In the luggage fabric segment, it has made two new innovations – one is increasing strength to weight ratio and the other is making it abrasion resistant.

Increasing the strength to weight ratio is imperative when it comes to the backpacks that students need to carry. To achieve this effect, the fabric and the processing technology have been redesigned and also the in-house coating recipe and as a result Nobletex now offers the lightest in weight material for backpacks.

When it comes to making luggage fabric abrasion resistant, Nobletex has the distinction of being the first company to introduce this feature where the fabric is used at the bottom of the backpack to give it durability and increase longevity. Using high tenacity yarns and specialized coating has helped the company achieve the desired abrasion resistant quality to the fabric.

Yet another first for Nobletex was when it developed the reusable PPE coverall fabric as per the specifications from the DRDO and SITRA. The PPE was made using specialized coating formulations that made the material light in weight, breathable and resistant to blood and viruses.

Nobletex continuously works with DRDO to develop fabrics for a variety of applications for the Indian defense.

Market Reach & Product Range

Nobletex currently commands a strong position in luggage and backpack fabric segment catering to the bulk of the leading brands in India. In coated industrial fabric segment, the company is one of the largest producers of PVC coated fabrics which are in high use as truck tarpaulins, awnings, in biofloc fish tanks and as tensile fabrics.

The company caters to the armed forces where the fabric is used to make protective clothing and gears. It makes outdoor fabrics that are used in manufacturing performance sportswear and apparel, then in the luggage and backpack fabric segment, Nobletex makes PU and PVC coated fabrics, interlining material and EVA foam laminated fabric too. The PVC coated industrial fabric is high-density coated fabric which is sturdy and reliable.

Vision 2025

Nobletex believes that market expansion, lean manufacturing and developing higher value-added products is what will help achieve its vision. A clearly defined long-term strategy and continuous efforts to build on initiatives, exploring different and new business avenues will be a pursued determinedly, so that market expansion is easier and faster.

Focusing on lean manufacturing where all the costs are being challenged from a zero-based budgeting principle will help the company build a leaner, flexible, and agile business model with enhanced customer-centric approach.

Its strategy is to focus on higher value-added products to achieve a CAGR of 25% and improve the bottom line net margins with current infrastructure and minimal CAPEX.

In a nutshell, Nobletex is committed to manufacture strong, long lasting technical material that meet the consistently increasing challenges in consumer, outdoor, industrial and military demands.