V4 impregnable fish nets operate with excellent antifouling results

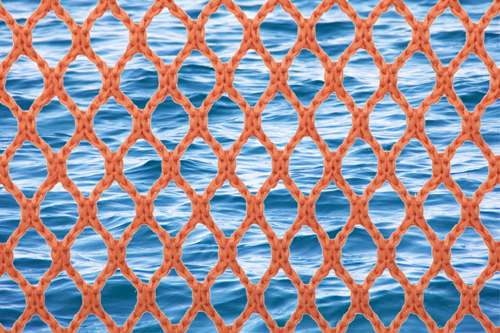

Global leader in technical textile solutions for aquaculture, launches to the market with a high-density polyethylene net, paintable with traditional water-based antifouling paints, unique in its category on the market, contributing R&D to the industry.

The impregnable Star V4 polyethylene nets are the new onslaught of Garware Technical Fibres in Chile, being the only ones on the global market that can be painted 100% with traditional water-based antifouling paints. “Until before this technology, HDPE was not paintable. With its development, the nature of the fiber surface is modified, allowing traditional paint to be perfectly fixed with complete compatibility”, explains Marcos Jofré, Business Associate Garware Chile.

After the detection of the cleanliness situation in Chile, the subsequent technological development in India and the performance of tests with Star V4 fattening nets in the farming centers of local salmon farmers, “today over 50% of salmon companies are conducting tests or permanently using the Star V4 nets, yielding good results, both in impregnation and antifouling; since the Star V4 net has even better impregnation than the traditional Star net. And not only have they been impregnated, but in several cases, they have even been re-impregnated, surpassing the second cycle of impregnation. For this reason, we ensure that Garware’s V4 technology impregnates HDPE with traditional water-based antifouling paints, confirming its effectiveness”, emphasizes Jofré

In addition, it maintains all the characteristics of the original raschel nets -knotless- Star, after 10 years of use, even under aggressive in situ cleaning conditions. The loss of tensile strength is of the order of 15%, compared to nylon which loses 40% or more in four years. Does not elongate, shrink, or lose its characteristics over time; It has a high resistance to abrasion in humid conditions, incorporates anti-UV additives and has the highest manufacturing standards worldwide. “Polyethylene with antifouling does not lose resistance over time, which provides great flexibility in the strategic process of cleaning the nets, since it is possible to migrate from impregnation to cleaning in situ or viceversa with ease to deliver the better conditions for salmonids, complying with the new regulations required by the sectoral authority”, adds Jofré.

Although paints for polyethylene can paint any nets, their cost is higher and in Chile there are no more than three brands, while traditional paints for nylon exist at least 10.

It should be noted that in-situ cleaning in Chile is still a complex activity in the aquaculture industry, basically due to logistical aspects ( distances from the farming centers, availability of services, costs, number of days in which it is not possible to work in the centers, etc.), for which the majority of aquaculture companies prefer to use nets with antifouling, a situation different from the rest of the world where cleaning in situ prevails, reducing the use of antifouling. www.garwarefibres.com