KARL MAYER is focused on producing functional textiles with multibar raschel machines. And functional yarns offer exceptional performance profiles. Warp knitted textiles combine the stability of woven fabrics with the elasticity of knitwear. Different thread systems can also be combined with warp knitting technology to produce fabrics with a wide variety of properties.

KARL MAYER has been working extensively on developing this segment in which electrically conductive and high tenacity materials are processed on multibar raschel machines. When producing technical articles, functional yarns can be arranged in areas of any shape, size and placement owing to their diverse potential.

Preferred Partner with Innovative Ideas

KARL MAYER Textile Makerspace is a platform that supports the development of latest innovations and combine them with new applications that are outside of the traditional textile machinery business. It combines the textile sector with new technologies, coming up with innovations such as RAPID-TEXTILE and TEXTILE-CIRCUIT.

RAPID-TEXTILE brings additive manufacturing to the textile industry. Printing directly on to a fabric is possible with technologies like Selective Laser Sintering, Fused Deposition Modeling and print with 2 components. And footwear industry is just one of many that is taking advantage of 3D printing technology by printing functional elements such as reinforcing structures on to stretched fabrics. When relaxed, the 3D prints ensure that the upper assumes the required shape without moulding.

Direct printing on textiles during the production process allows for creating opportunity to design textiles individually.

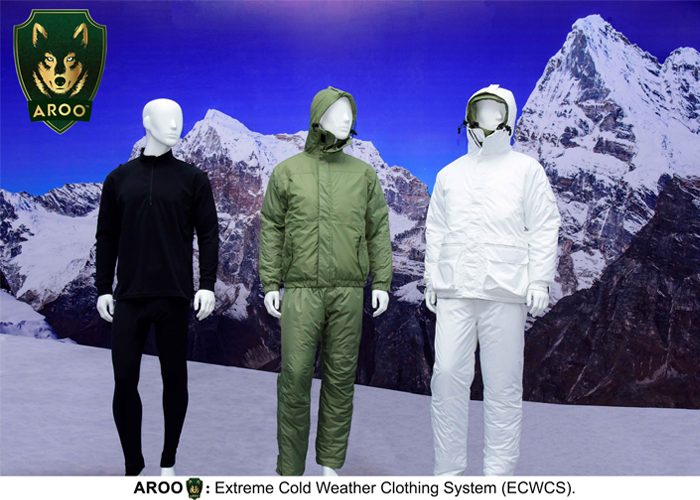

TEXTILE-CIRCUIT integrates electrically conductive yarns into warp knitted textiles directly on the machine. Warp knitting is fast and versatile while enabling functional materials to be incorporated directly on the machine in line with the application and results in products with typical textile properties like softness, elasticity, flexibility and breathability. Warp knitting is used across active and sportswear, lingerie, outdoor wear, automotive and agricultural fabric segments.

Smart Way to Electrically Conductive Textiles

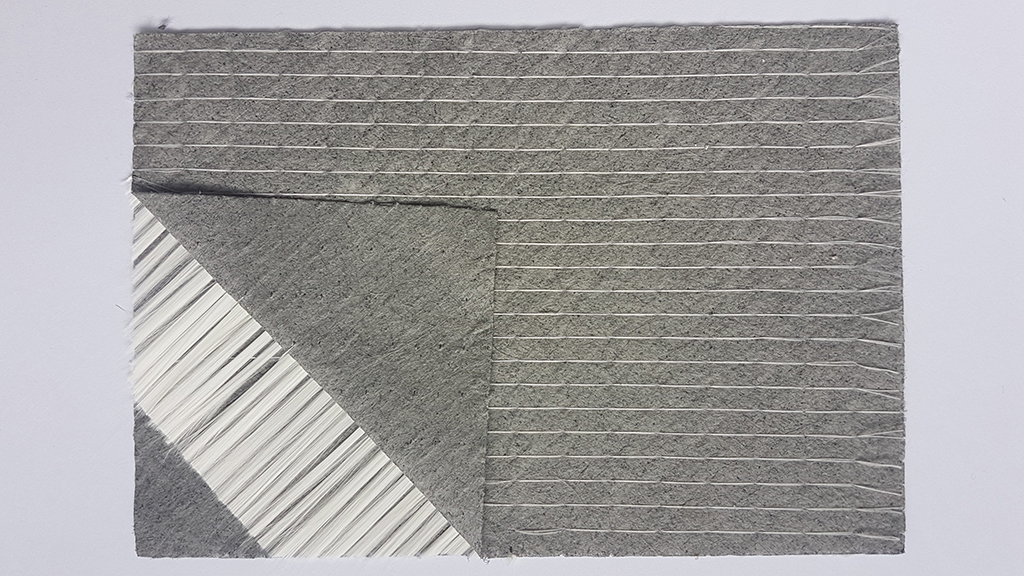

Directly integrating electrically conductive yarns into warp knitted textiles enables functional elements such as sensors, conductors and coils to be incorporated in a smooth manner minus the additional production steps or compromising the textile characteristics.

Sophia Krinner, Product Manager – KARL MAYER has been investigating the possibilities as part of TEXTILE-CIRCUIT using silver coated filaments such as ELITEX®, Silvertech, Shieldex® and Agsis™. Even fine insulated metal filaments and metallized yarns like ELITEX® TPU and Percon® isolated could be used – depending on the flexibility and diameter. It was realized that the yarns must be matched to the properties of the desired textile and to the machine gauge in terms of bending stiffness and radius.

Non-insulated filament yarns can be used on current machines with additional voltage monitoring, and a specific modification of the yarn guiding is recommended when using insulated metal filaments. TEXTILE-CIRCUIT allows for arm sleeves to control robots, textile charging stations with coils of electrically conductive yarns to inductively charge smartphones and sports shirts with integrated sensors to measure heart rate, temperature and humidity. Another case in point is a clothing solution that uses Bluetooth-enabled app for communication. An advancement in this solution has come in the form of an electrode with a soft 3D shape that offers more skin contact and thus delivers a better signal. It reinforces the development in technology that has the best combo of a comfortable fit of clothing with smaller electronics while offering greater scope for design.

High Tenacity Yarns for Reinforced buttonholes

A series of tests have been conducted by the brand to test the process of high tenacity materials on the string bars of multibar raschel machines. Using functional thread variants, different structures to reinforce holes were created. The entire structure of the produced textiles was tested in terms of tear resistance. The tests were based on the standardised grab tensile test and an in-house test that was used for measuring the hole tensile strength. It was found that the tensile strength was significantly lower across all test specimens than that of the pure high tenacity material, since the base fabric always gave way first. However, compared to the basic fabric made of pure polyamide, strength values were significantly improved by all the functional materials used. In the most extreme cases, the hole tear resistance of the basic structure could be quintupled by individually placed, high-strength weft threads, and the tensile strength of the fabric increased eight-fold.

Multiple patterns with multibar

A combination of jacquard and multibar patterning is the pre-requisite for the extraordinary patterning possibilities of multibar raschel machines. The split jacquard bars are full set threading and produce a basic structure that can be creatively designed using a single needle motion, while string bars with multibar patterning incorporate additional yarns into the diverse ground structure to add a functionality. The added thread material is supplied by bobbins, so it does not have to be warped onto warp beams.