An exclusive interview with Lothar Kaierle, Vice President – Sales Nonwovens, American Truetzschler, at IDEA Miami 2025

At the heart of the nonwovens industry’s evolution lies the convergence of sustainability, localization, and next-generation technology. At IDEA Miami 2025, The Textile Magazine caught up with Lothar Kaierle, VP – Sales Nonwovens at American Truetzschler, to explore the company’s latest innovations, regional strategies, and its unwavering focus on efficiency and circularity.

Highlights at IDEA: Refining the Known, Revealing the New

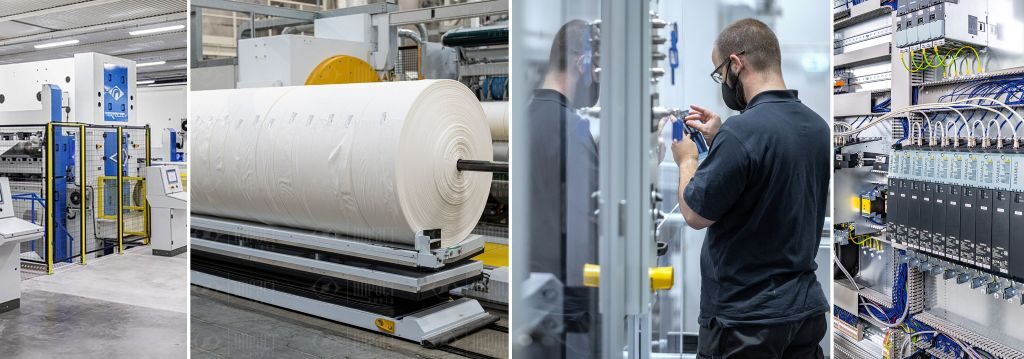

While American Truetzschler didn’t unveil an entirely new machinery line at IDEA, the company emphasized meaningful advancements in existing technologies. One standout is its collaboration with Italian-based Texnology resulting in the launch of T-SUPREMA — an integrated needlepunch line optimized for a broad range of applications.

“This development touches geo and automotive textiles, filtration, acoustic insulation and other smaller sectors where high-performance nonwovens are essential,” Kaierle explained. “We’re refining individual machine components to achieve greater energy efficiency and virtually zero waste production.”

Innovation Through Industrial Synergy

Truetzschler’s innovation philosophy centers on optimization and integration. The company’s high-performance dryers, for example, are engineered to maximize thermal efficiency, especially critical in energy-sensitive regions like Europe.

“Energy efficiency is top priority,” said Kaierle. “And from a sustainability perspective, we are proud that our systems enable zero fiber waste within the plant. Everything that enters the production line leaves as usable material.”

Wherever possible, good fibers are collected and fed back into the production process. Dust collection is also thoughtfully addressed. The minimal dust that does accumulate is filtered and properly disposed of, with efforts underway to integrate this waste into third-party recycling loops through partnerships with companies like Balkan.

Automation, Efficiency, and Circularity: The New Norm

Automation and closed-loop production are central to Truetzschler’s response to industry demands. Kaierle noted, “Every fiber introduced at the beginning of the process is accounted for by the end. That’s what zero-waste means to us—not just a marketing term, but an engineering goal.”

The company’s advanced carding and web-forming systems are designed for seamless integration with energy-optimized dryers and bonding units, reducing both material loss and operator dependency, which is increasingly valuable in regions facing labor shortages.

North America: High on the Global Growth Agenda

With reshoring efforts intensifying in North America, especially post-pandemic, American Truetzschler is positioning itself as a key enabler for regional capacity building. Kaierle shared that while spunlace and air-bonded nonwoven investment projects in the U.S. are still in early stages, interest has surged significantly.

“Several manufacturers are evaluating how to relocate or expand production within the U.S. due to geopolitical shifts and tariff barriers,” he said. “These are multi-year investment decisions, but the intent is clear. I expect we’ll see real momentum by next year.”

India: An Expanding Giant in Nonwovens

India remains a crucial part of Truetzschler’s global strategy. The company recently expanded its presence by relocating operations to a larger plant in Ahmedabad, which is one of the largest facility for cotton spinning machines within Truetzschler globally, with over 1,200 employees. Indian companies are also investing on new Nonwoven projects, supported by Truetzschler’s technology.

“India, along with Pakistan and Bangladesh, represents one of the largest textile markets worldwide,” Kaierle acknowledged. “While my colleagues in India are best positioned to elaborate, it’s clear that the nonwovens opportunity in South Asia is enormous and still unfolding.”

Strategic Priorities: A Global Perspective

Looking ahead, Truetzschler is prioritizing growth in three key regions:

• North America: Driven by nearshoring and demand for high-quality hygiene and industrial nonwovens.

• MENA (Middle East and North Africa): With oil-exporting countries now diversifying into downstream industries, including polypropylene- and polyester-based nonwovens, especially in geotextiles.

• South America: An emerging opportunity fueled by growing consumer demand and government support for domestic manufacturing.

“Anywhere with a rising population and developing industry base is a market of interest for us,” Kaierle noted. “With strategic investments and regional adaptability, Truetzschler sees a bright future across all major nonwoven markets.”

Conclusion

At IDEA 2025, American Truetzschler reaffirmed its role as a technology leader and a sustainability advocate in the nonwovens sector. Through innovations in needlepunching, drying, waste recovery, and plant-level circularity, the company is helping manufacturers reduce environmental impact while scaling production. With its eye firmly on the future, Truetzschler is building a globally integrated, regionally focused, and environmentally conscious roadmap for nonwovens.