VANDEWIELE team is delighted to welcome its customers again at the next edition of the Techtextil exhibition, in Frankfurt, Germany.

TEXTILE INNOVATIONS TOGETHER

VANDEWIELE has always acted as technological leader and innovative player in the textile machinery industry.

Innovation technology and customer centricity are our drivers for developing new products. Our innovations aim to impact on the customer’s value chain; we want to be together as partners and offer not only innovative products, but also our expertise and solutions to be able to satisfy customer needs. TEXTILE INNOVATIONS TOGETHER is our philosophy and summarizes our customer-oriented approach.

VANDEWIELE, the expert in weaving

Get inspired on our Techtextil stand by the large range of Vandewiele solutions and accessories. We have some stunning presentations of new realizations in the field of woven technical textiles, feeders and other developments for multilayer fabrics, spacer fabrics, etc… Today’s machinery allows already manufacturing the most complex 3D geometries and composites for hybrid lightweight construction. After visiting our booth on Techtextil, you will be convinced that there is still an enormous number of open opportunities!

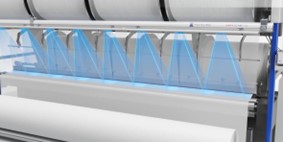

At Techtextil Vandewiele will show several examples of technical textiles based on the core technology of double piece distance weaving creating a sandwich structure.

The Vandewiele group of companies has in house all the required technologies. Our Vandewiele weaving machines create sandwich structures by weaving two fabrics bonded together by vertical yarns. The Vandewiele IRO zero twist feeders gives you full control of the weft. The warp is controlled by our Vandewiele Bonas full electronic jacquard machines. The technology of the use of servo motors in all our machines is controlled in house from Vandewiele – Aros producing all types of motor and drive solutions.

Superba, already the leader in heat-setting with saturated steam under pressure thanks to their well-known TVP3, is now offering the KR1: a brand-new automatic knotting system assisted by a robot. The KR1 system can be used in many industrial branches, enables to handle, pack and label bobbins. With this machine, SUPERBA’s commitment is to help customers to improve their productivity thanks to an industrial robot running 24/7. Suitable for DTY, BCF, Artificial Turf, Tyre Cord, Tape & more.

On finishing side, the Bejimac singeing machine has been used for decades in technical textiles and in particular for filtration purpose. The nature of the manufacturing process of the needle felt creates hairiness on the surface of the product. The first purpose of singeing is to remove this hairiness. Then, specially for technical textiles, we can use a technique to create a glazing effect on the felt itself (usually on one side). We will be proud to present you the new developments made in order to substantially reduce the gas consumption while offering high intensity singeing.

The revision of the MESDAN-LAB family of tensile strength testers has been completed with the launch of the NEW double column model, TENSOLAB 50kN, code 2515E at the TECHTEXTIL 2024. It is a unique solution for the testing of high-tenacity technical textile materials, up to the maximum capacity of 50kN (5.000 kg).

The new TENSOLAB 50kN embodies a combination of the best ingredients: latest technology, best electronics, new software & new interchangeable accessories, stunning performances (in terms of capacity, versatility, accuracy, and testing efficiency), and of course Italian design and the Mesdan’s 30-year experience in dynamometer R&D and manufacturing.

To complete the strength tester family, besides the semi-automatic single column “TENSOLAB 4”, the range includes the single-position automatic “AUTODYN 3”, endowed with the automatic yarnloading device, also suitable for fibres, hanks and fabrics and garment accessories, the fully automatic 24-positions yarn strength tester “AUTOFIL”, and the well-known portable SPLICE SCANNER.

Protechna supplies advanced fabric and thread control systems that ensure the quality of your products. We recently introduced an updated camera technology that checks the quality of your technical fabrics (multi axial / woven) made from carbon / glass fibers. Our camera system ARRAYCAM 5430 detects a big variety of fabric defects and stops the textile machine immediately.

In addition, we will display our system for tension control for direct warping TENSOSCAN 2 5374 and our slub detection system for sectional warping COGASTOP CREEL 2 3210

MEMMINGER-IRO supplies the leading yarn feeding technology to feed carbon, copper, wire, monofilament, polyamid and other sophisticated yarns to all kind of knitting machines for the production of technical textiles. The corresponding products such like storage feeders, electronic feeders and unspooling device will be exhibited during Techtextil in Frankfurt.

Zero defect manufacturing with Loepfe yarn sensors

Electronics, transportation, food and many others – Loepfe is the preferred partner for a wide range of industries when it comes to zero-defect manufacturing. Loepfe WeftMaster products ensure, for example highly stress-resistant tarpaulins, the best sound for smartphones and animal feed bags that can withstand long journeys undamaged. One example: by using the unique detection features of Loepfe’s FALCON-i yarn sensor to remove smallest fluff or filamentation from the weft-yarn, waste is dramatically reduced in the carbon fabric production process. The applications where FALCON-i can improve product quality are nearly unlimited. Weavers with a focus on high quality technical textiles benefit from using FALCON-i to improve the quality of their products while avoiding customer claims or expensive patching.

Sedo Treepoint will be showing selected products in the field of ecology and quality control that will allow companies to focus on greater flexibility and efficiency in their production. Our automation solutions as well as testing and quality control systems support in all aspects of the textile dyeing and finishing business. Our key topics include resource optimization and energy efficiency, for which Sedo Treepoint integrates innovative ideas and concepts into the systems. While sustainability and efficiency have always been of great importance in the textile industry, they have become increasingly important in recent years. In the area of quality control, Sedo Treepoint will show you solutions that contribute to improved color communication, production data acquisition, authenticity checks and many more. Sedo Treepoint is your expert for industrial and process automation to master these challenges

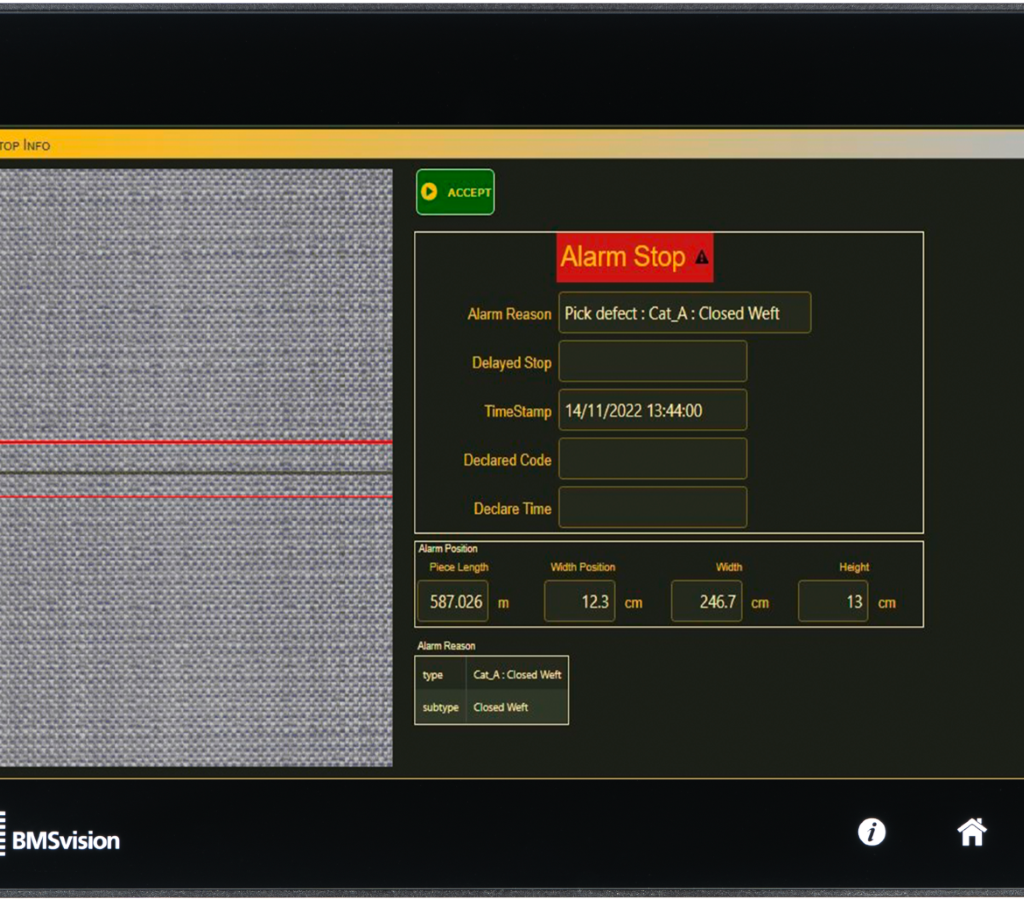

BMSvision, expert in Manufacturing Execution Systems (MES) for the entire textile industry, has been at the forefront of MES integrations since 1975. Based on decades of expertise and by using advanced technologies, BMSvision’s MES-solutions enable users to efficiently collect, correlate and visualize data, transforming into actionable insights. The various software modules include real-time monitoring, scheduling, reporting, maintenance, quality and energy monitoring, amongst others. BMSvision’s MES-solutions not only optimize operational, quality and energy efficiency but also pave the way for sustainable growth. In addition to its MES-solutions, BMSvision will also showcase Argus at Techtextil. Argus is part of our camera-based AI on-loom inspection systems for high-end technical textiles, jacquard fabrics such as OPW airbag and mattress ticking.

All the Vandewiele machines can be connected through cloud computing to the “TEXconnect” supervision system to comply with the Factory 4.0 concept.