Supported by a Strategic Partnership with A.T.E. Enterprises

Exclusive Interview and Pics by K. Gopalakrishnan

India’s man-made fibre industry is entering a new phase of modernization and expansion. With growing domestic demand and a strong governmental push to strengthen the country’s presence in polyester, nylon and technical textiles, advanced machinery manufacturers are stepping forward to support this transformation. Among them, STC Spinnzwirn GmbH, a global leader in extrusion and high-speed winding technologies, is sharply focused on India as a major market for both new investments and modernization. During an interaction at Techtextil India, Mr. Harald Mueller, Regional Sales Director, reflected on the company’s history, expertise and ambitious plans for India—further reinforced by a newly announced strategic partnership with A.T.E. Enterprises.

A Legacy of High-Performance Machinery for MMF and Technical Textiles

Founded in 1866 and belonging today to the Austrian Starlinger Group, STC Spinnzwirn specializes in two core areas:

1) Complete extrusion lines for:

• slit-film tapes used in carpet backing, baler twines, geotextiles and greenhouse twines

• monofilaments made from LDPE, nylon and polyester for artificial grass, ropes, shade nets, geotextiles and paper machine clothing

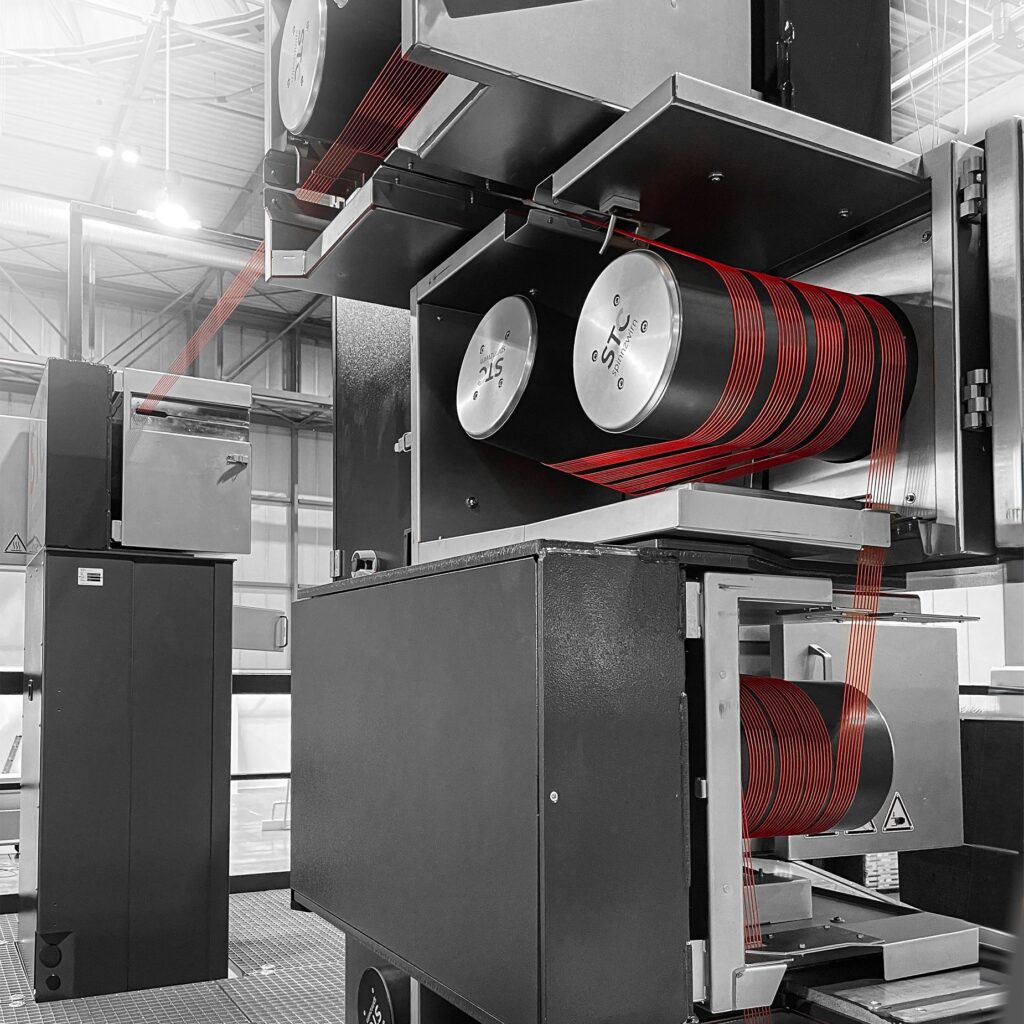

High-speed take-up solutions, including:

• advanced drawing technology using heated and ambient godets

• automatic winders ranging from 800 m/min to 5500 m/min

• unique traverse systems: camshaft, camshaft with grooved roll (ASW) and rotary/bi-rotor systems

These systems are engineered to deliver exceptional package quality, ensuring smooth downstream performance on high-speed weaving, knitting and processing equipment.

What makes STC particularly attractive for Indian customers is its ability to upgrade and modernize existing spinning lines, especially where original suppliers no longer offer spare parts. Harald highlighted this capability:

“Our winders can fit directly into existing lines, giving machines a second life. There is no need to replace everything—modernization can be achieved with smart upgrades.”

India: A Strategic and Growing Market

STC Spinnzwirn’s global footprint spans Asia, the Middle East, China and South America, but India stands out as one of its most important and promising regions. The country’s well-maintained older spinning lines, combined with rising investments in MMF capacities, create significant opportunities for modernization.

Harald observed: “India is a very important market for us, especially for multifilament equipment. The machines installed years ago are still in good condition, but many electronic spare parts are obsolete. This is where we step in.”

Key Indian players—including polyester, nylon and polypropylene producers—are actively exploring upgrades and new projects. STC has already worked with prominent companies such as Daman Polythread and Century Enka, and the current momentum suggests that more investments are imminent.

A Strong Start at Techtextil India

Though this was STC Spinnzwirn’s first participation in Techtextil India, the show delivered valuable engagements with existing manufacturers and new prospects. Harald appreciated the event’s timing and relevance:

“It was important for us to be here and understand the direction of the Indian market. We received new contacts and reconnected with existing customers.”

With the next ITMA India approaching and India’s MMF sector expanding, STC expects increased industry activity across polyester, nylon and polypropylene applications.

Market Trends: Modernization and Capacity Expansion on the Rise

While global geopolitical uncertainties have slowed down decision-making in many regions, India’s domestic demand continues to propel investment discussions. The government’s emphasis on strengthening the MMF ecosystem, coupled with incentives for expansion and import substitution, is pushing companies to diversify and scale.

Harald expressed optimism about the future: “Yes, I expect more investments—both in new plants and modernization. Now is the right time for companies to prepare for the next cycle. When the market returns, those who invested early will be ready.”

Indian textile giants that traditionally focused on cotton are now entering MMF in a significant way. Companies like Vardhman, Arvind, Filatex, Indorama and several new entrants are expanding into polyester and nylon fabrics, sportswear, industrial textiles and technical applications. This shift signals a long-term growth runway for machinery suppliers like STC.

Why Indian Manufacturers Prefer STC Spinnzwirn

In a competitive market where both premium European and lower-cost Asian machine suppliers are present, STC differentiates itself through:

• superior package formation enabling export-grade yarn quality

• robust, long-life designs suitable for demanding industrial environments

• compatibility with existing systems, reducing costs for modernization

• global engineering expertise backed by continuous innovation

• high-speed winding technology that supports faster downstream processing

Harald summed it up succinctly: “Quality matters. If customers want to export to Europe or the US, they need a machine that delivers a perfect package. That is what we offer.”

Strategic Partnership with A.T.E.: A Milestone for India and South Asia

In a major development, A.T.E. Enterprises Private Limited—one of India’s most respected textile engineering groups—has partnered with STC Spinnzwirn to promote and service its products across India, Bangladesh, Sri Lanka and Nepal, effective from 1 September 2025.

This collaboration significantly enhances customer access to STC’s advanced technologies, including:

• two-for-one twisters for multifilaments

• high-speed automatic winders

• precision winders for viscose, lyocell, acrylic and others

• accessories for spinning lines

• godets and take-up machines

• comprehensive spare parts support

A.T.E.’s Senior Vice President, Mr. Navin Agrawal, commented: “STC’s technology and engineering complement our mission to provide cutting-edge solutions to our customers. This partnership will greatly benefit the synthetic fibre industry in the region.”

Harald echoed this confidence: “A.T.E. has deep market knowledge and technical capability. Their service excellence and enthusiasm will help us support customers even better.”

STC Spinnzwirn’s growing engagement in India comes at a defining moment for the country’s man-made fibre and technical textiles industry. With increasing investment in polyester and nylon, rising demand for high-performance yarns and the need to modernize aging infrastructure, STC’s advanced extrusion lines and high-speed winding technologies are well positioned to support India’s transformation.

The new partnership with A.T.E. takes this commitment further, ensuring world-class access, faster service and stronger market outreach. As India strengthens its position in global MMF and technical textiles, STC Spinnzwirn is set to play a pivotal role—helping manufacturers upgrade capabilities, improve yarn quality and prepare for the next wave of growth.