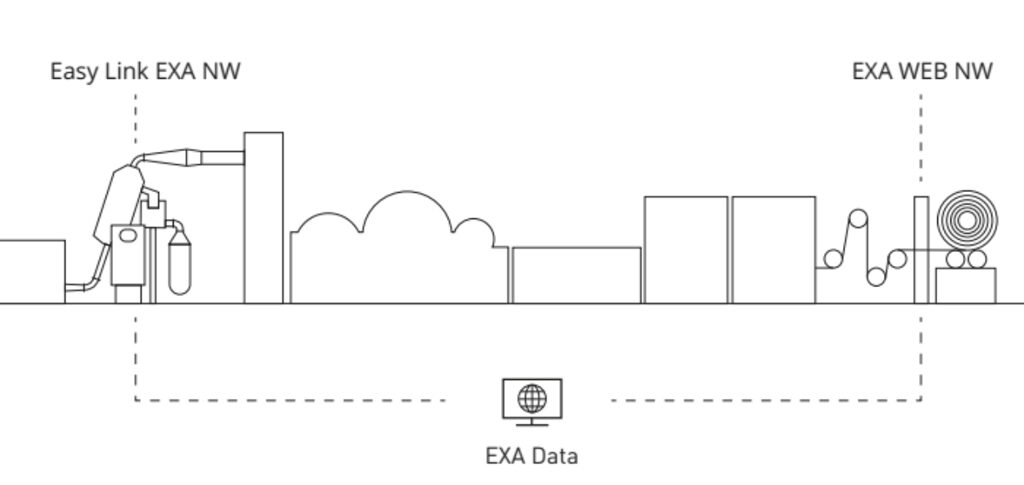

Loptex is delighted to present a comprehensive solution for contamination reduction and control in Nonwoven lines. This application is specifically designed for carded fibers used in the production of finished webs for hygiene and medical purposes. The innovative Sorter Easy Link EXA NW is strategically installed at the opening point, preceding the carding process. It excels in high accuracy and precision, efficiently detecting even the smallest visible contaminants. Additionally, it provides total control over raw materials during the preparation process, significantly contributing to the reduction of contaminants in downstream processes. The modular concept ensures customized solutions for all types of blow room lines.

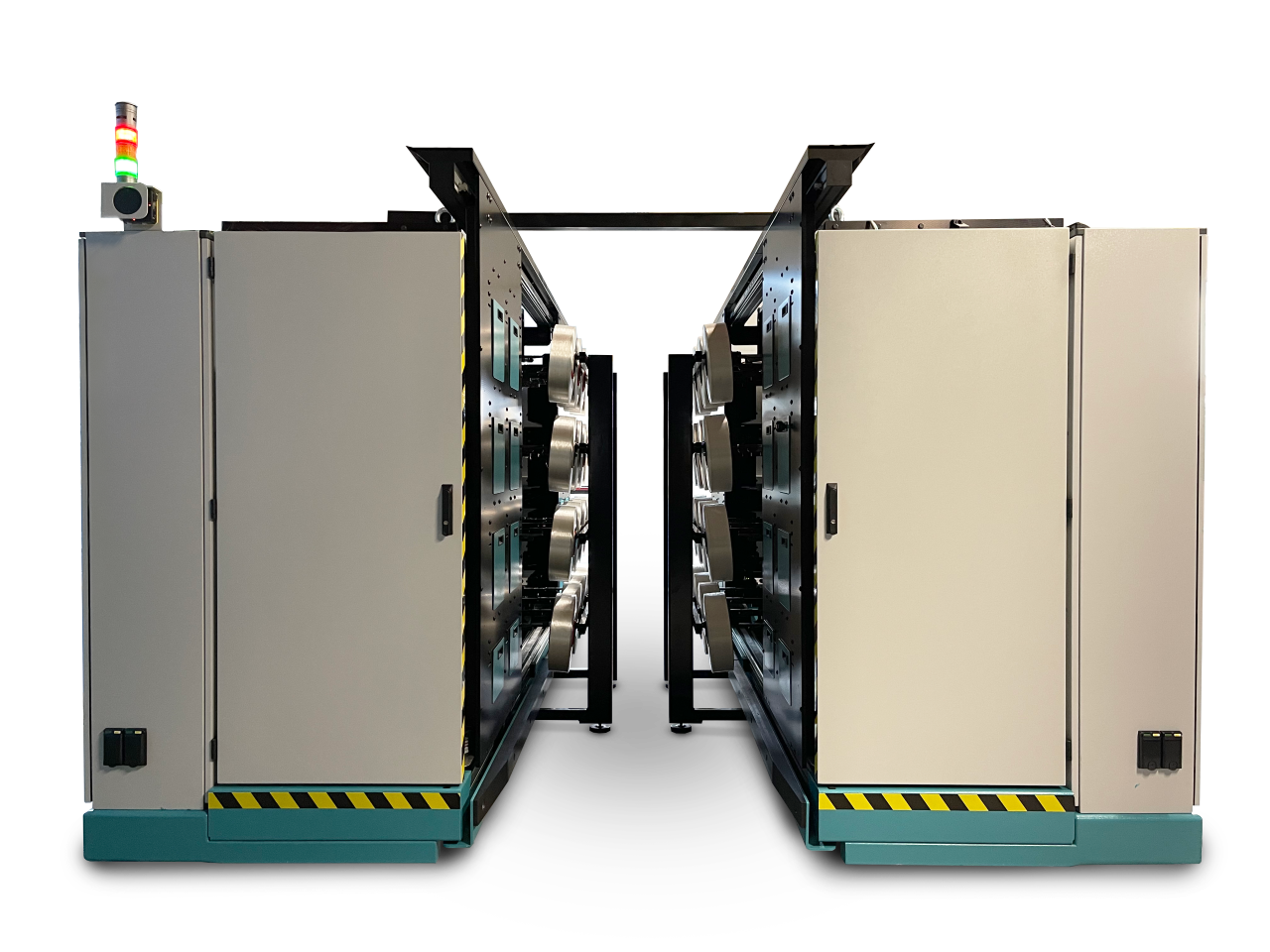

The newly introduced EXA Web NW system is dedicated to inspecting finished webs before winders. This system meticulously controls remaining contamination and material imperfections through arrays of embedded color camera systems and LED illumination sources. The combination of EXA Web NW and Easy Link EXA NW not only reduces the content of contamination in raw materials but also optimizes control over the finished web. Moreover, it identifies the origin and cause of contamination at every stage of the production process.

The synergy of EXA Web and Easy Link EXA NW results in a significant improvement in the quality of finished webs, leading to enhanced production yield. Loptex continues to innovate and elevate standards in Nonwoven processes with these cutting-edge solutions.