Producing high-quality yarn takes perfection in heat treatment, drawing and tension. Retech is one company that has the right kind of know-how and experience on how to achieve the required results. And most of all how to get the best out of tools such as different godets, components and process monitoring systems – all vital elements in a comprehensive solution.

Considered a global leader in technology and components for the heat treatment of synthetic fibres, Retech has had a successful run in 2022. The Swiss company known for its strong research and development capabilities looks forward to consistency in good performance and is ready to showcase its expertise come ITMA 2023. “The year 2022 was a successful one and we are pleased with the outcome. The highlights were the various customised draw frames we were able to successfully build for multinational big players,” said Managing Director Rolf von Arx in an exclusive chat. Sharing details about the company’s product range for the global market, he said, “Our products are focused on heat treatment and drawing synthetic filaments and we are a major market player for heated godets.”

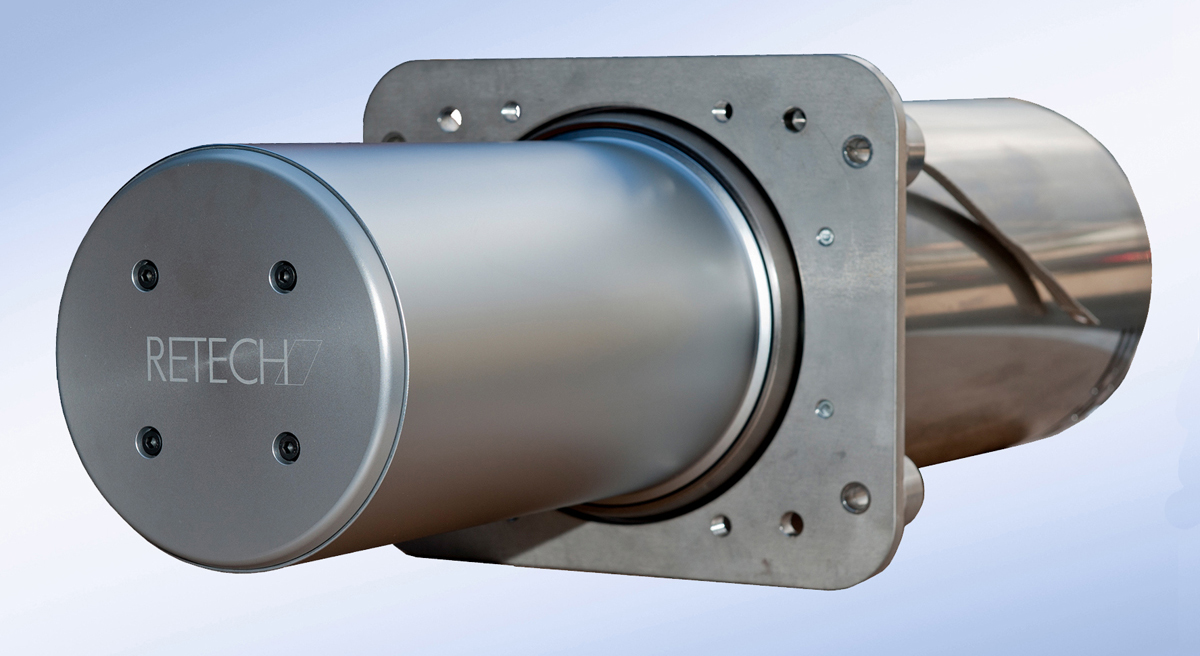

“Most of the OEMs place complete trust in our products and solutions,” he added. Pointing out the key global markets where Retech has a strong presence and the ones where the future holds strong potential, Arx stated, “Europe is still our key market as most of the OEMs are based in this region. Furthermore the US market is most important and we command a strong position there. The emerging markets are China, Korea and Southeast Asia including India, where we are putting in our best efforts and investments and achieving positive results.” Retech has built a strong reputation for using technology to enable a larger diameter and the required heating capacity within limited space.

Technology Leader

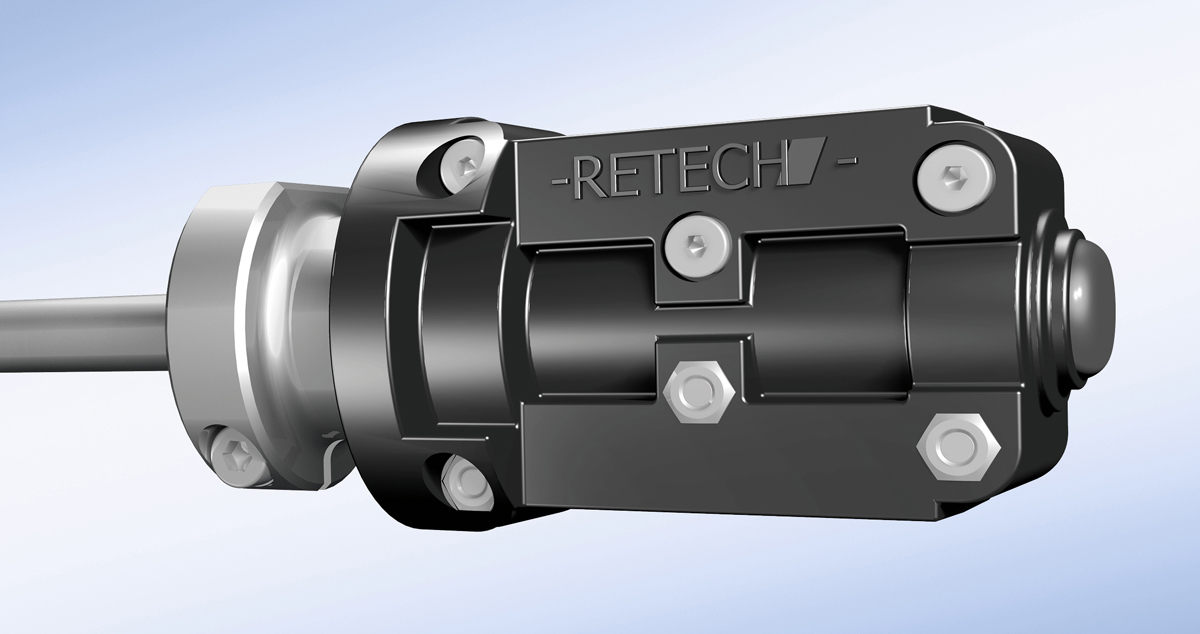

Highlighting a key recent innovation in technology offered by Retech, Arx said, “Our present focus is on the ongoing development in heated godet technology and we are proud to be able to offer a system that brings sustainability to a new level. Implementing Internet of Things (IoTs) into the heated godet and be able to supervise induction heater and bearing temperatures helps tremendously to achieve an even longer lifetime.” The company is all set to showcase its technological prowess at the forthcoming ITMA 2023. “The limelight will be on the introduction of the mentioned IoTs within a heated godet. We will show this on a demonstration unit and explain the immediate effects of vibrations and other negative temperature effects,” Arx said.

“Furthermore, we will show on the same demonstration unit how the famous ‘blue thread’ is created,” he added. One of the underlying themes of ITMA 2019 was the focus on Industry 4.0. When queried on what’s next in terms of manufacturing, automation and digitisation for Retech, Arx said, “As mentioned earlier, we have developed and integrated further sensors, monitoring devices and algorithms to achieve longer lifetime, less downtime and higher productivity for the manufacturer and in the end more sustainability.” Elaborating on how the company’s products and technologies ensure sustainable manufacturing, he said, “Our products are always ahead compared to other existing solutions.”

“We are convinced and proud to be able to offer heated godets with well-advanced technology allowing a more sustainable production of synthetic filaments by using less energy to heat and draw the fibres, reuse the created losses within the heated godet itself and reduce CO2 emissions to ensure the desired level of sustainability,” he further said. Underlining the company’s key strengths, Arx stated, “Next to the already mentioned points related to our solutions and products, we are offering a major additional advantage: the customer is the main focus and we do everything to achieve our customers’ goals and wishes. Retech does not offer off-the-shelf solutions but customised products dedicated to the customer’s needs with a high level of integrity and commitment to the project.”

Retech customers are partners, rather than just buyers. “Most of our customer relations started when companies took Retech on board to solve problems in fibre processing,” Arx added. So what are the management’s expectations for 2023 for the growth of the textile industry globally? Replying to the question, Arx said, “The year 2023 will not be an easy one. In some fields we feel that the market capacities are not being fully used. A lot of uncertainty in the global world harms new investments and therefore we are less optimistic, as has been the case in recent years. However, due to our good and strong position with high-quality products operating in a niche market, we are still positive about the outcome for this year.”