Today, softness is no longer a secondary requirement in hygiene products like baby diapers and feminine care products – it’s a pre-requisite so satisfy demanding consumers. Technology and advanced engineering are keys for manufacturing absorbent hygiene products that deliver full functionality and overall comfort.

Web quality – the essential pre-requisite for premium nonwovens

Every premium nonwoven product begins with one essential factor: excellent web quality.

To achieve a perfectly homogeneous web, Trützschler’s T-BLEND fiber preparation system ensures precise control from the very beginning. It manages gentle fiber opening, accurate dosing, blending and continuous fiber feeding to the nonwoven card.

Carding and web forming is the heart of the process. The advanced nonwoven cards handle every fiber with precision. Fibers are further blended and formed into a uniform web with consistent weight distribution and fiber orientation across the full working width.

Whether standard, coarse, ultra-fine, short or long fibers, Trützschler systems deliver excellent carding and blending performance, ensuring high-quality fiber webs at high throughput. For the specific requirements of ATB bicomponent fibers, e.g. PP/PE or PET/Co-PET fibers, Trützschler Nonwovens has developed a dedicated solution to ensure optimal processing.

Trützschler Nonwovens carding excellence: designed for the future, built for results

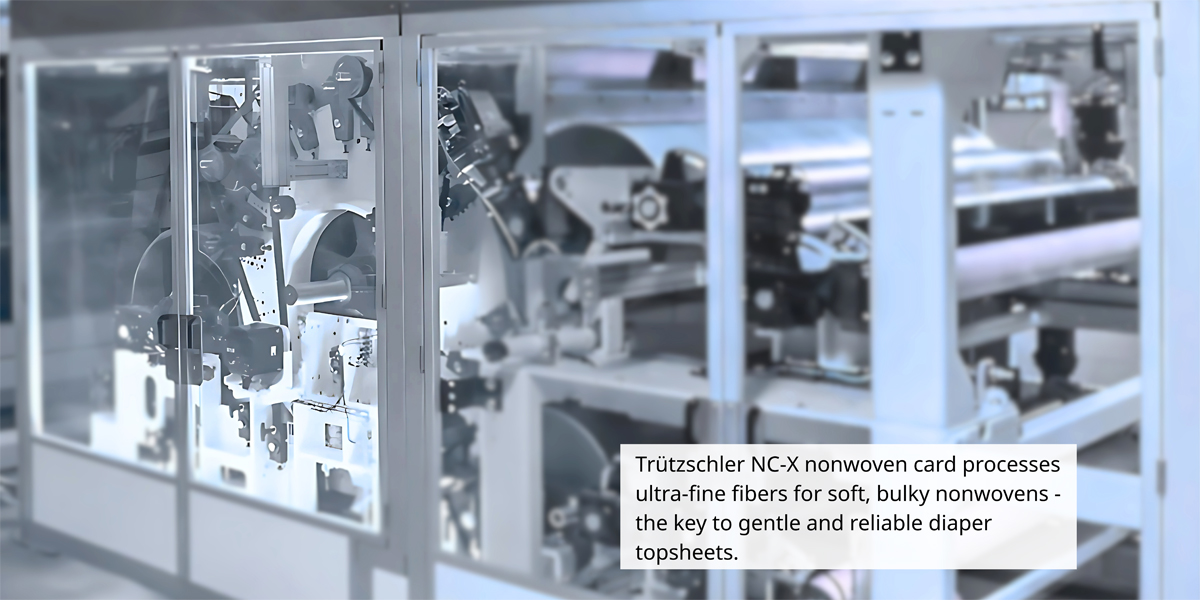

Trützschler Nonwovens offers industry-leading roller carding technology designed for maximum uptime, high efficiency, and outstanding flexibility. The multi-purpose NC-X card – compatible with ATB, hydroentangling, and needle-punching lines – handles web weights from below 15 to over 130 g/m² and working widths up to 4,200 mm, making it ideal for hygiene applications.

Trützschler’s Clean Card concept integrates precision – engineered casings, advanced sealing systems, and powerful dual-side suction to dramatically reduce fiber fly and dust buildup. Easy-access design allows faster cleaning and maintenance, ensuring a clean production environment and maximized uptime. The flexible web forming section supports a wide range of customizable web structures.

Powered by high-precision wire solutions for nonwoven cards from sister company Trützschler Card Clothing (TCC), Trützschler Nonwovens delivers more productive tailored innovations – precisely aligned with the needs of real-worlds nonwoven production.

Revolutionizing softness in hygiene products

Modern baby diapers represent sophisticated textile engineering. They balance comfort, hygiene, and performance through precisely designed multi-layer constructions. A diaper’s typical four-layer architecture comprises

– a skin-friendly, thin topsheet of 15 to 25 gsm (gram per square meter) to quickly take-in liquid and prevent re-wetting,

– the Acquisition and Distribution Layer (ADL) to laterally spread liquid,

– the absorbent core to safely store liquid,

– and the backsheet which prevents leakage.

Each component must perform specific liquid management functions while providing ergonomic fit, flexibility in movement and comfort throughout the diaper’s lifecycle.

The air-through bonding renaissance: where functionality meets softness

ATB technology is experiencing renewed prominence for premium topsheets and increasingly for backsheets. This trend is driven by breakthrough polymer and fiber spinning developments. On the forefront for premium qualities now are ultra-fine 0.8 and 0.6 denier sheath/core bicomponent fibers that deliver exceptional softness when processed correctly. Web bonding relies on hot air: as the bulky fiber web passes through the heated oven, thermoplastic sheaths melt and bond around core fibers, creating lofty, breathable structures with superior feel compared to conventional, cheaper spunbond alternatives.

Trützschler’s technical excellence

Trützschler Nonwovens delivers proven ATB solutions through flexible line concepts featuring one or two nonwoven cards, customized to the specific requirements of nonwoven topsheets. The foundation for quality is laid by the established T-BLEND fiber preparation system, engineered to also handle demanding microfibers that tend to entangle.

The specialized NC-X cards for hygiene applications reliably process fibers well below 1 dtex, ensuring optimal parallelization, minimal entangling and consistent high-loft webs. This combination delivers the bulky, soft nonwovens essential for baby comfort while maintaining the structural integrity required for reliable diaper performance.

Beyond baby care

ATB technology also extends into feminine care applications such as sanitary napkins and pantyliners though sustainable alternatives are gaining traction. For soft products with a natural texture, Trützschler’s comprehensive portfolio includes production lines for hydroentangled nonwovens from sustainable cotton or viscose fibers. All lines feature the proven AquaJet spunlacing technology, complemented by the innovative MPD drum dryer for energy-efficient drying.

The scalable concepts range from high-speed multi-card lines to compact configurations using Trützschler flat-top cards. They all enable manufacturers to produce superior both femcare products and wipes with consistent quality on the same production line.

“Make in India”: Local production with German expertise

Trützschler Nonwovens brings industry-leading expertise in globally proven nonwoven manufacturing technologies. In China, sister company Trützschler Textile Machinery (Jiaxing) Co., Ltd. (TTMJ) has delivered nearly 100 carding machines for ATB lines, currently holding more than 90% of the market share. Today, Trützschler’s nonwoven card is the only solution on the market that reliably processes ultra-fine fibers – down to 0.6 denier – on an ATB production line.

To keep product and process quality in nonwoven production on the highest possible level, Trützschler Nonwovens offers T-ONE – a digital work environment that supports production teams in their daily work. Industry 4.0 and AI technology implements a central data hub collecting and using all production-relevant data to enable digitalized quality control, recipe management, real-time monitoring and process optimization.

Across Asia, Trützschler Nonwovens offers strong technical and service support to local nonwoven manufacturers. Sister companies TTMJ in China and Trützschler India Private Ltd. (TIPL), based in Ahmedabad and Sanand and covering 36,000 square meters, provide localized expertise, spare parts supply, manufacturing capabilities, and TCC wire solutions. In Vietnam and Indonesia, regional service hubs ensure fast response and hands-on assistance. With targeted training and practical support, the company help producers across region optimize product quality, strengthen local value chains, and enhance global competitiveness.