As India’s textile industry undergoes a paradigm shift, Prashant Group stands tall as a pioneer and leader in weaving preparatory machinery. Celebrating its golden jubilee in 2025, the company’s journey from a modest shed to a globally recognized engineering house is a compelling narrative of Indian innovation, entrepreneurial spirit, and long-term vision.

At the helm of this transformation is Ms. Amoli Shah, Director and second-generation leader, who has infused new energy into the company’s strategy through a focus on technology, automation, exports, and inclusive growth.

From a Small Workshop to a Global Engineering Brand

Prashant Group was founded in 1975 by Mr. Prakash Shah, father of Ms. Amoli Shah, with just four people in a small workshop. Over the last five decades, the company has grown exponentially with multiple manufacturing plants spanning a vast area and employing over a thousand people today. “It started as an engineering unit, and then in the 1980s, we entered textile machinery through narrow fabric machines. The real turning point was our collaboration with Gamatex, Italy for sectional warping machines,” says Ms. Shah.

What sets Prashant apart is its deep manufacturing integration. The company produces most of its mechanical components in-house, using advanced laser cutting machines, CNC bending equipment, and plasma technology. This vertical integration has given Prashant complete control over quality and delivery timelines, while enhancing innovation speed.

Strategic Joint Ventures: Forging Global Partnerships for Technological Excellence

Prashant Group’s evolution into a global leader in textile machinery was significantly shaped by its strategic cooperations with world-renowned companies—Gamatex (Italy), WestPoint (USA), and Ferber s.r.l. (Italy). These collaborations brought in advanced technology, strengthened the Group’s engineering foundation, and accelerated the localization of sophisticated textile machinery for Indian and global markets.

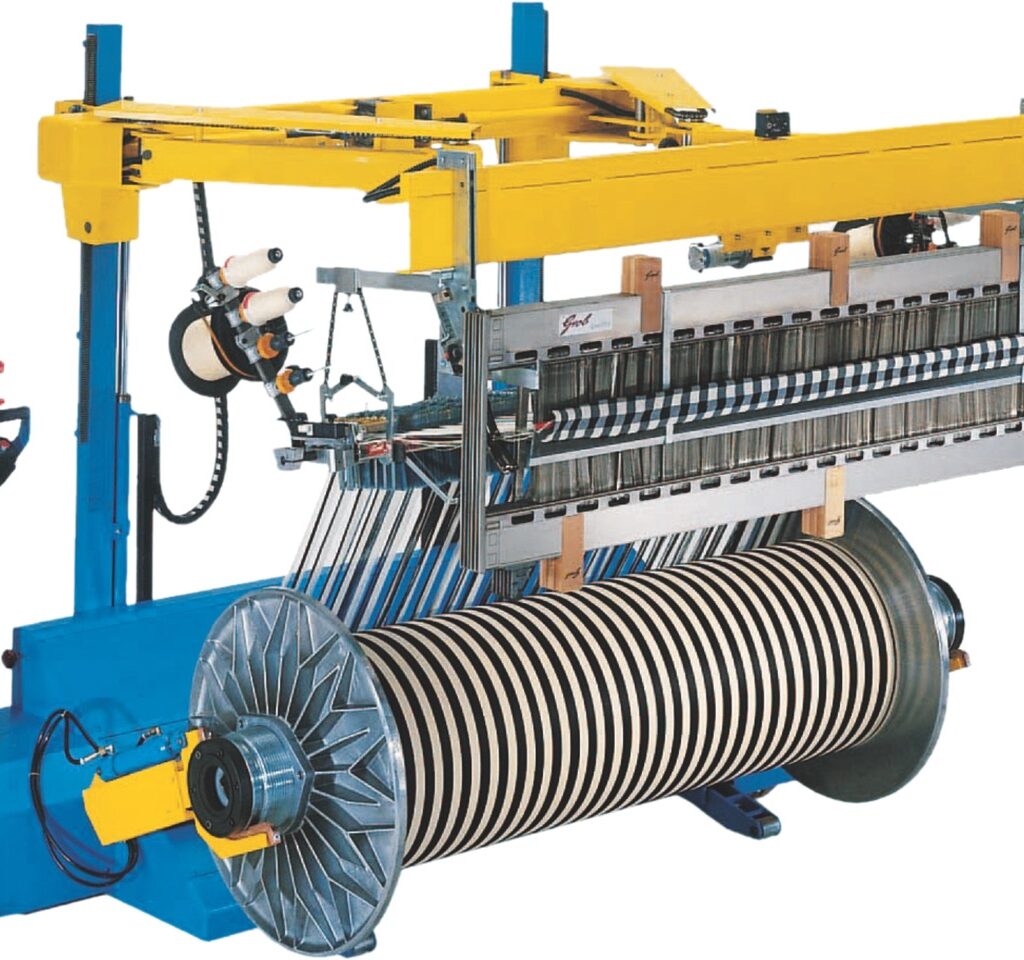

1. Gamatex (Italy): Introducing Sectional Warping to India

The collaboration with Gamatex in the early years was a turning point, bringing modern sectional warping technology to India at a time when such machines were largely imported. This collaboration empowered Prashant Group to offer high-quality warping solutions suited to Indian conditions, at competitive prices.

“The Gamatex partnership introduced us to precision engineering and robust design principles that continue to guide our manufacturing today,” shares Ms. Amoli Shah.

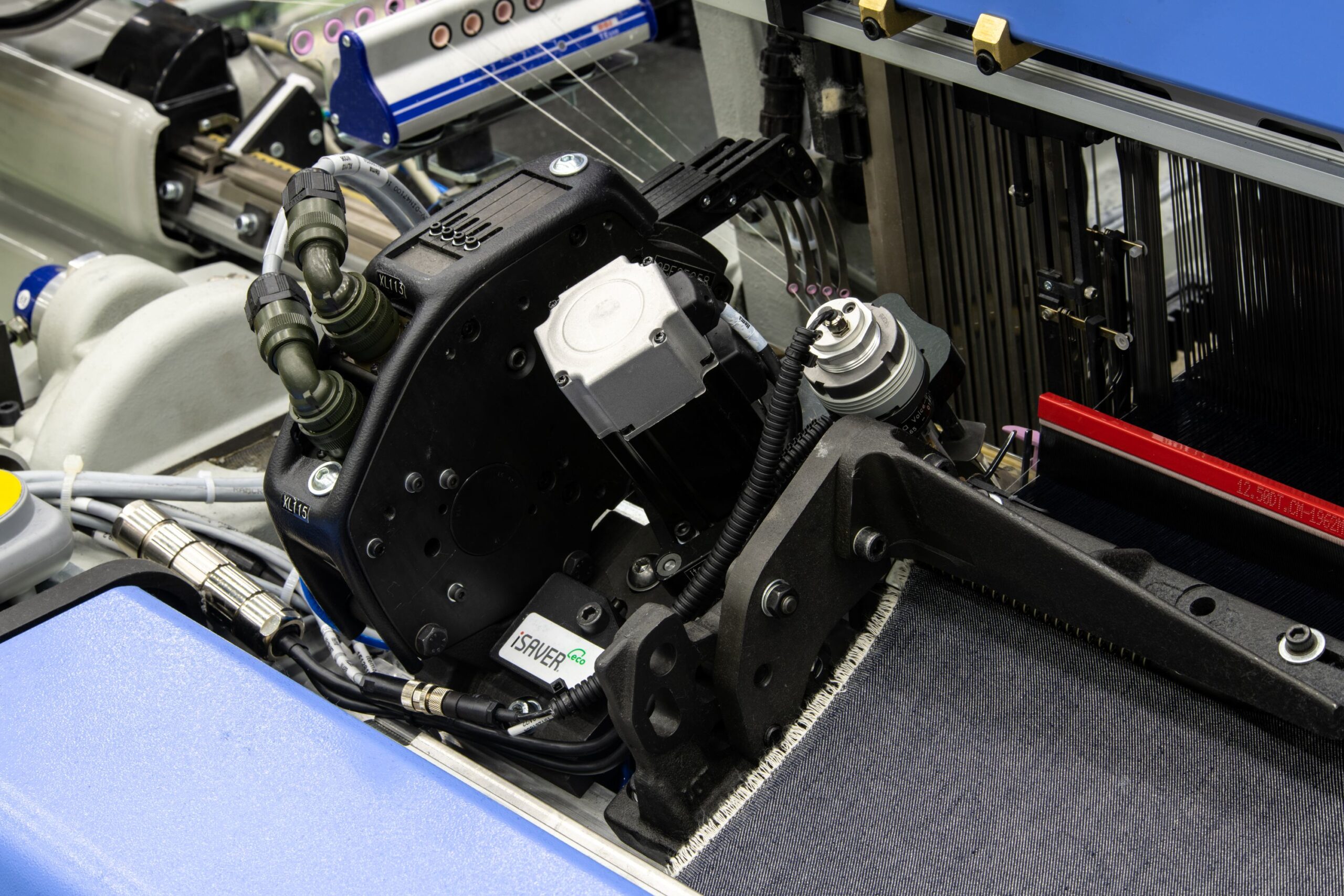

Having internalized the technology over time, the Group eventually began developing indigenized, advanced versions of sectional warping machines, integrating servo controls and automation—cementing its leadership in the warping segment.

2. WestPoint (USA): Expanding into Sizing and Direct Warping for spun and technical textiles.

The tie-up with WestPoint marked Prashant Group’s entry into Sizing and direct warping machines, for spun and filament yarn.

“WestPoint helped us diversify into a new category of machines tailored for modern weaving requirements,” says Ms. Shah. “They continued to recommend Prashant to their global clientele—a reflection of our capability to carry their legacy forward.”

The knowledge gained from this alliance laid the groundwork for Prashant Group’s continued innovation in modern weaving preparatory machinery.

3. Ferber (Italy): Engineering Smart Beam Handling and Storage Solutions

In joint venture with Ferber s.r.l., Italy, Prashant Group established Prashant Ferber, which has become a leading supplier of warp beam handling and storage systems in India and abroad. The JV focuses on the manufacture of manual and motorized warp beam handling systems, computerized automatic beam storage, and fabric roll storage, inspection, and packaging solutions.

This partnership brought advanced European automation and safety features to Indian mills, addressing critical challenges in material movement, space optimization, and operator safety.

“Our solutions with Ferber have enabled mills to improve productivity and reduce downtime through intelligent storage and handling,” adds Ms. Shah.

Today, Prashant Ferber’s systems are deployed in leading mills across India and other countries, offering world-class automation and integration with weaving and finishing operations.

Comprehensive Product Portfolio

Over the years, Prashant Group has built an impressive product range in weaving preparatory machinery:

- Sectional Warping Machines – for cotton, filament, viscose, technical textiles, and even glass fibers

- Direct Warping and Beaming Machines – including specialized poly beamers for PP and HDPE tape fabrics

- Sizing Machines – for a wide variety of yarn types: spun yarns, filaments, jute, viscose, and fiberglass

- Indigo Dyeing Machines with Nitro Technology – a patented, sustainable solution that reduces the dyeing process from 8 tanks to 2, saving 60% water, 50% chemicals, and significant energy

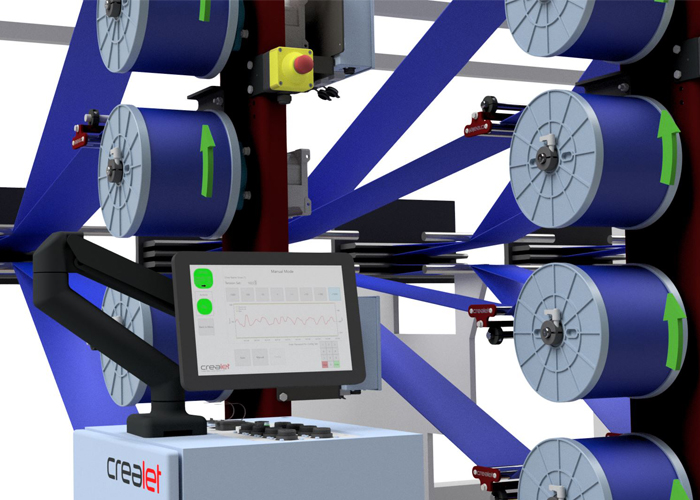

- Robotic Warping Machines – a fully automatic warping solution with auto leasing

- Tensioners and Automation Systems – including a patented high-end tensioner for technical fabrics

- Material Handling & Storage Equipment – such as motorized and manual trolleys, vertical computerized beam storage systems, inspection machines and batching motions

Recent developments include a pile beam trolley for terry towels, advanced tensioners for technical fabrics, and a split warping machine in response to increasing demand from Surat and South India’s weaving clusters.

Technology & R&D: At the Core of Growth

From the very beginning, Prashant’s vision has been to deliver world-class machines at appropriate prices, enabling Indian weavers to reduce dependence on imports. Strategic technology collaborations—initially with GammaTex (Italy), West Point (USA), and Ferber (Italy)—allowed the company to gain a strong base in European design and performance standards. Over time, Prashant’s own R&D strength took the lead, helping it develop proprietary technologies and secure multiple patents.

“We don’t just replicate technology—we constantly improve it. Our machines are not static products; they evolve with customer feedback and global benchmarks,” Ms. Shah notes.

This philosophy has enabled Prashant to consistently outpace domestic competition, especially in sectional warping, where the company enjoys over 60% market share in India and a strong footprint across 50+ countries, including Europe, North America, South America, Turkey, and Russia.

Leadership in Automation & Industry 4.0

A major area of focus under Ms. Shah’s leadership is the integration of automation and AI across the product line. Prashant’s newer machines now come equipped with:

- Real-time data monitoring systems

- SCADA-integrated dashboards for central control

- Predictive maintenance features based on sensor readings

- Remote diagnostics and software upgrades for global clients

“Today, about 70% of our machines are Industry 4.0 ready. Over the next three to four years, we aim to integrate automation and AI compatibility across the board,” shares Ms. Shah.

The group’s vision includes complete factory automation, even in material handling, with motorized trolleys, conveyors, packing systems, and remote-controlled inspection systems.

Responding to Market Shifts with Agility

Ms. Shah acknowledges the volatile global business environment—from geopolitical tensions to shifting trade dynamics between India, Bangladesh, and China. Despite this, she remains optimistic: “India is resilient. After every downturn, there is always a sharp rebound. We may not grow exponentially each year, but the textile sector will continue its upward trend.”

She also notes how Indian weavers are moving up the value chain, investing in higher-performance machines, particularly in segments like MMF (man-made fibers), filaments, and technical textiles. Prashant Group is already seeing a surge in demand from major players like Arvind, Kusumgar, Vardhman, SRF, Khosala and many more for MMF sizing and specialized warping.

Sustainability at the Core

Prashant’s innovation is strongly aligned with sustainability goals. The company’s Nitro Indigo Dyeing technology is a standout success in this area, reducing environmental impact significantly. In-house operations are also green-focused—solar panels power all buildings, tree plantations adorn factory premises, and the company invests up to 1% of its turnover (not just profit) in CSR initiatives, including education, tribal development, and rainwater harvesting projects in South Gujarat.

A People-Centric Company Culture

Ms. Shah credits Prashant’s long-term success to its people: “We’re lucky to have employees who’ve been with us for over 20 years. That loyalty has helped us build a knowledge base that can’t be replicated overnight.”

She also encourages women in engineering and manufacturing, with women employed across design, HR, admin, and even non-labor-intensive shop floor roles.

Ms. Shah herself brings a unique leadership perspective, having joined the company after earning her mechanical engineering degree, Master’s in IT, and MBA from the USA. Together with her husband Mr. Apurva, who leads the product design and operation division, she has driven major growth since joining the business in 2004.

The Road Ahead: Focused Growth and Smart Expansion

Looking forward, Prashant Group plans to:

- Expand its export footprint in Asia, Africa, and Europe

- Launch gap-filling products in its existing weaving preparatory portfolio

- Continue to invest in automation, AI, and data-centric machine designs

- Strengthen its technical textiles offering, especially for demanding applications like fiberglass, PP tape fabrics, and carbon composites

“There’s always room for improvement,” Ms. Shah concludes. “Today’s best machine will be obsolete five years from now. So, we are always pushing to raise the bar.”

50 Years of Legacy, and a Future Built on Innovation

Prashant Group’s 50-year journey is not just a celebration of endurance but also a story of continuous evolution, global thinking, and Indian innovation. With a strong foundation in engineering, an eye on digital transformation, and leadership committed to sustainability and customer success, the company is well-positioned to lead the textile machinery sector for the next 50 years.

As the industry prepares for a smarter, more sustainable future, Prashant Group—under the leadership of Ms. Amoli Shah—is ready to lead the way.