Monforts is going all out to reiterate its ace position in 3 key fields of advanced coating, denim finishing and fabric sanforizing. The company is participating at the Innovate Textile & Apparel (ITA) Virtual Textile Machinery Show 2020 which is on between October 15-30.

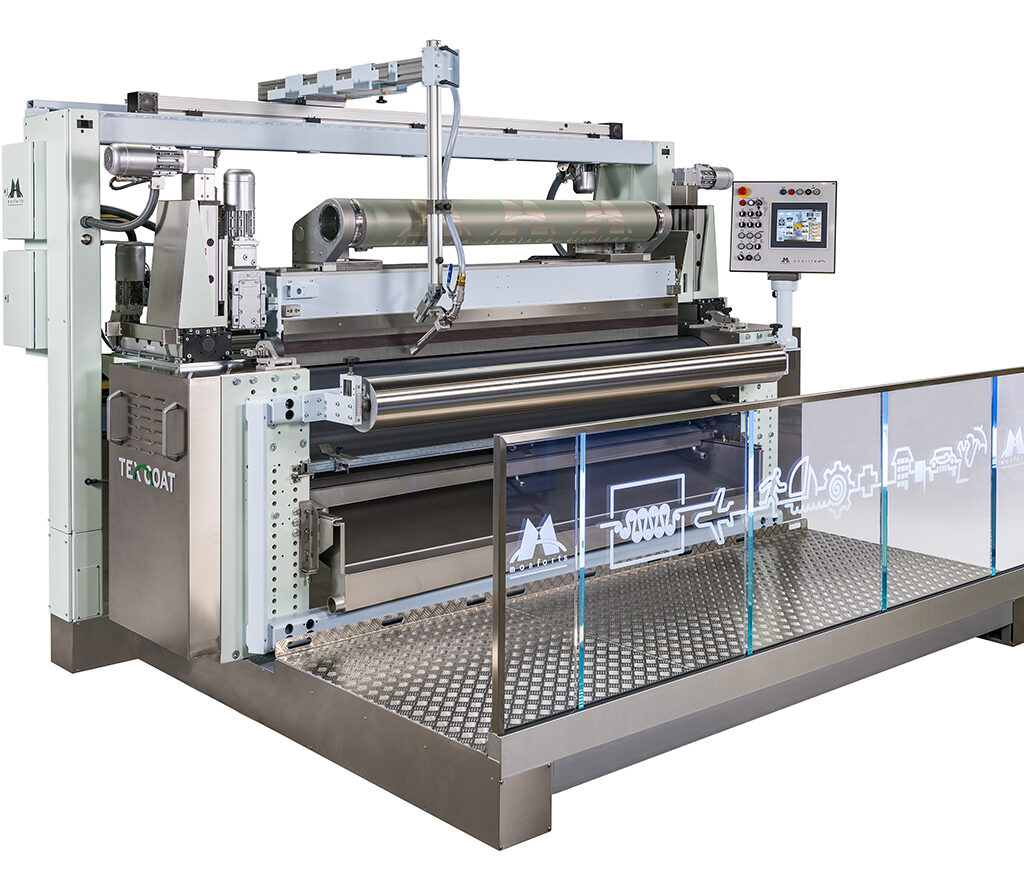

With its multi-head capability, the latest Monforts texCoat coating system provides the flexibility as per the market requirement.

Jürgen Hanel, Head – Technical Textiles, Monforts shares: “Since we acquired the coating technology, we have made multi-fold refinements and all of them are reflected in higher coating accuracy. We are the only manufacturer to offer completely integrated coating lines from a single source and the coating machine is tailored to the subsequent Monforts drying technology – with all the benefits resulting from fully integrated plc control.”

He further says: “Our systems have the shortest fabric path from the coating unit into the stenter and we have all variations of coating application systems too. And all of these options are available in wider widths, with the engineering and manufacturing from a single source here in Europe.

CYD Yarn Dyeing System

Hans Gerhard Wroblowski, Head – Denim, Monforts explains: “CYD is based on the proven Econtrol® dyeing system for fabrics. It integrates new functions and processes into the weaving preparatory processes – spinning, direct beaming, warping and assembly beaming, followed by sizing and dyeing – in order to increase quality, flexibility, economic viability and productivity. The CYD system has been developed in response to a strong market demand.”

Sanforizing – Monforts Style

Usually, sanforized denim shrinks about 2-3% while unsanforized denim shrinks up to 10%. And Monforts has delivered a significant number of latest Monfortex sanforizing lines to customers around the world.

Sanforizing is vital to final fabric quality, pre-shrinking it by compressing prior to washing to limit any residual or further shrinkage in a made-up finished garment to less than 1%, for perfect comfort and fit over an extended lifetime.

As with industry-leading Montex stenters, Monfortex lines benefit from the latest Qualitex 800 control system which allows all parameters to be easily automated via the 24-inch colour touchscreen, including production speed, control of all fabric feed devices, rotation spray or steaming cylinder options, the width of the stretching field and the rubber belt pressure. Up to 10,000 separate process parameter records can be generated and stored by the data manager.