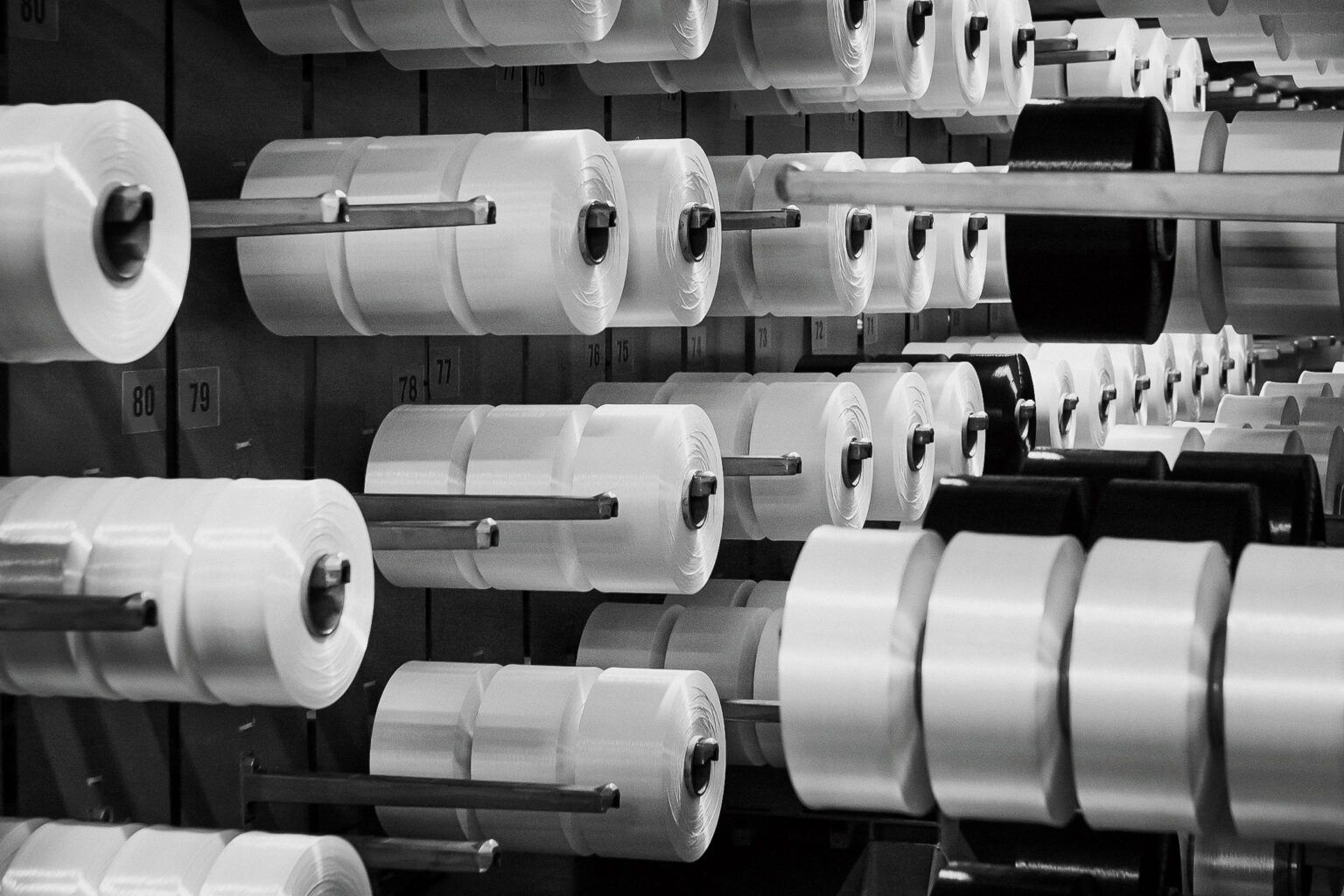

As India’s man-made fibre (MMF) industry gains renewed momentum through supportive policy measures and improved global market access, Filatex India Limited continues to consolidate its position as a leading polyester yarn manufacturer with a strong focus on circularity and value-added growth. The Company delivered stable financial performance in Q3FY26 and the first nine months of FY26, while advancing major strategic projects in recycling, renewable energy, and automation—reinforcing its long-term sustainability-driven growth roadmap.

For Q3FY26, Filatex reported standalone revenue from operations of ₹1049.70 crore, while revenue for 9MFY26 stood at ₹3175.03 crore. The performance reflects stable volumes, disciplined execution, and a continued shift toward higher-value products.

Commenting on the results, Madhu Sudhan Bhageria, Chairman & Managing Director, stated:

“I am pleased to share that the Company delivered a strong performance during the quarter, with stable revenue, supported by constant volumes, improving margins, disciplined execution, and our continued shift towards higher-value products. This reflects the strength of our operating model and our ability to perform consistently in a dynamic environment.”

The Company’s performance comes at a time when global textile markets remain influenced by regulatory shifts, pricing dynamics, and evolving sustainability requirements.

Strategic Project Execution: Expanding Scale and Circular Capacity

Filatex is currently executing multiple capital expenditure projects aimed at strengthening its competitive positioning.

Textile-to-Textile Recycling Project

A ₹300 crore textile-to-textile recycling project with a capacity of 26,750 tonnes per annum (TPA) is progressing as scheduled, with commissioning targeted for September 2026. This initiative marks a significant step toward building a closed-loop polyester ecosystem in India and aligns with rising global demand for traceable recycled fibres.

PFY Brownfield Expansion

The Company is also undertaking a ₹235 crore brownfield expansion, adding approximately 55,000 TPA, primarily in Fully Drawn Yarn (FDY) and Draw Textured Yarn (DTY). This expansion supports product mix enhancement and value-added portfolio growth, reinforcing Filatex’s focus on premium and performance-driven applications.

Renewable Energy Transition

Filatex continues to accelerate its renewable energy transition, sourcing power from hybrid wind-solar and solar projects. The Company aims to increase its renewable power share from around 26% to nearly 55%, with commissioning targeted for November 2026. This move will significantly lower carbon intensity and support sustainability commitments demanded by global brands.

Automation and Efficiency Upgrades

An auto-doffing and packing line automation project, implemented in collaboration with an Italian technology partner, is scheduled for completion by June 2026. The initiative is designed to enhance operational efficiency, reduce losses, and improve shop-floor productivity.

Collaboration with Decathlon India: Driving Recycled Adoption

Through its wholly owned subsidiary Texfil Private Limited, Filatex has signed a Memorandum of Understanding (MoU) with Indeca Sporting Goods Pvt. Ltd. (Decathlon Group) to collaborate on the adoption of recycled polyester in sports apparel.

This partnership signals growing global brand interest in traceable and circular polyester solutions manufactured in India. It also reinforces Filatex’s positioning as an early mover in textile-to-textile recycling and sustainable polyester production.

Industry & Regulatory Landscape: Emerging Tailwinds

Several industry and policy developments are creating favourable conditions for the Indian MMF sector:

- The non-imposition of anti-dumping duties on MEG has supported stable raw material pricing.

- Relaxation of Quality Control Order (QCO) norms has increased imports, partially affecting margins.

- Extended Producer Responsibility (EPR) and circularity norms continue to drive demand for recycled and traceable polyester.

- The Union Budget 2026–27 has strengthened policy backing for MMF and technical textiles through initiatives such as the National Fibre Scheme, Text-ECON, Mega Textile Parks, and SAMARTH 2.0.

On the global trade front, the proposed India–EU Free Trade Agreement is expected to reduce or eliminate tariffs on textile and apparel exports, enhancing India’s competitiveness in Europe. Additionally, a likely reduction in US import duties on Indian textile and apparel exports—from around 25% to approximately 18%—could further support export growth.

Reflecting on these developments, Mr. Bhageria added:

“Looking ahead, supportive policy measures, improving market access through recent India–EU FTA and sharp reduction in US tariffs, along with Europe’s sustainability-led sourcing shift are creating strong tailwinds for the Indian textile sector. With our scale, integrated manufacturing and early leadership in circular recycling, we believe Filatex is well positioned to benefit from these trends and drive sustainable long-term growth.”

Filatex India’s Q3FY26 and 9MFY26 performance underscores the Company’s ability to navigate market volatility while executing a clear, sustainability-focused growth strategy. With ongoing investments in textile-to-textile recycling, value-added polyester capacity, renewable energy transition, and automation, Filatex is building a resilient and future-ready manufacturing platform.

As global markets increasingly prioritise circularity, traceability, and low-carbon production, Filatex’s integrated model and early leadership in recycled polyester position it strongly to capitalise on policy support, trade agreements, and sustainability-driven sourcing shifts—both in India and across key export markets.