By K.Gopalakrishnan

Priya Darshani Designs Sets the Benchmark with new Installation

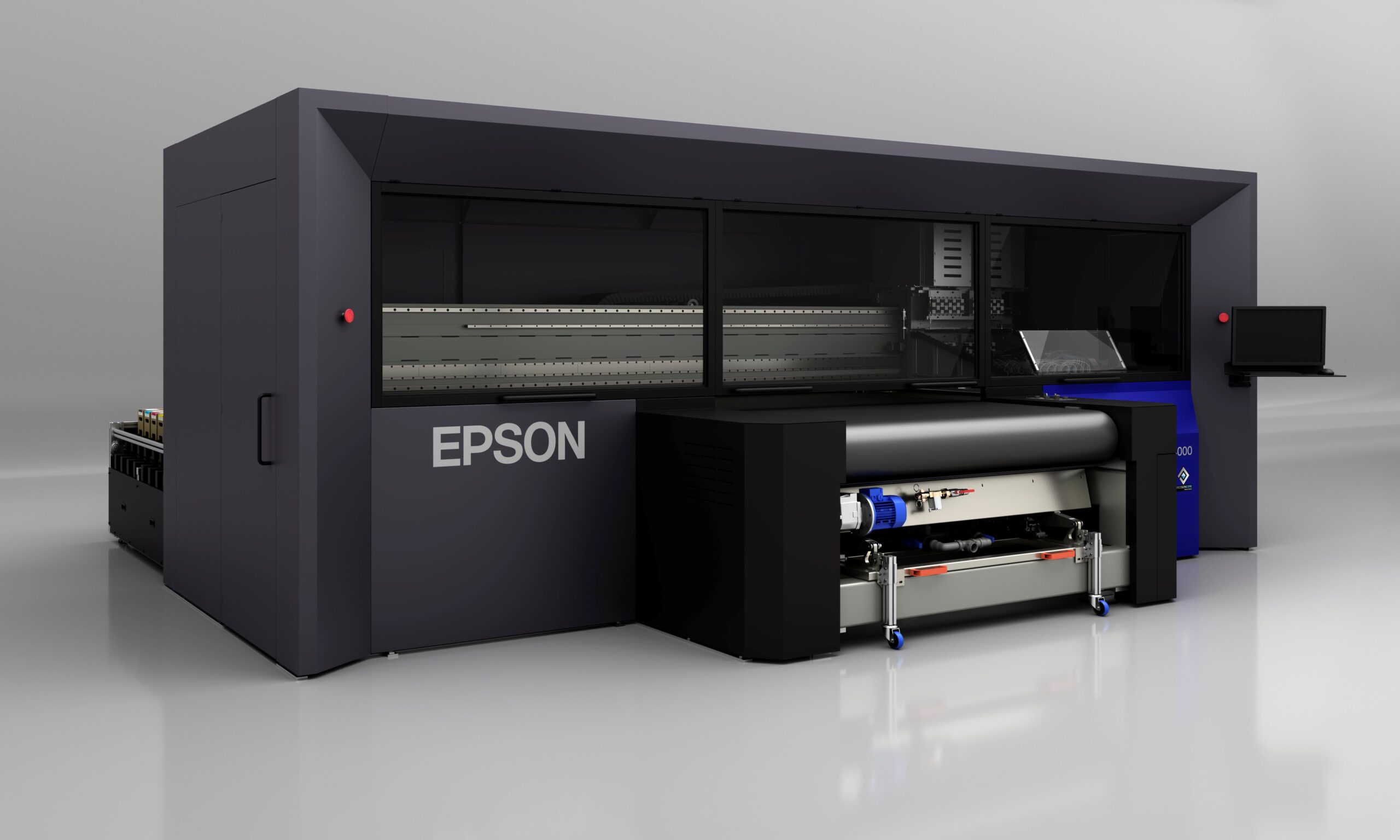

India’s textile printing industry is at a defining inflection point. As global markets demand faster turnaround, impeccable colour consistency, strict compliance standards and measurable sustainability, manufacturers are being compelled to rethink conventional production models. Against this backdrop, the installation of Epson’s flagship Monna Lisa ML-64000 with advanced pigment ink technology at Priya Darshani Designs marks more than just a technological upgrade—it signals a structural transformation in how textile printing is being approached in India.

In an in-depth conversation, Mr. S. Prabagaran, Senior General Manager at Epson India, reflects on this milestone, the accelerating shift toward digital manufacturing, and how Epson is positioning itself not merely as a technology supplier, but as a long-term solutions partner for India’s textile exporters.

A Landmark Installation for India’s Textile Industry

The installation of the 64 print head Monna Lisa ML-64000 at Priya Darshani Designs represents the first deployment of this advanced pigment ink-based system in India. For Epson, this is a pivotal moment. Priya Darshani Designs was already an Epson customer, operating the Monna Lisa ML-8000. Their decision to scale up to the ML-64000 reflects confidence not only in the machine’s performance, but also in Epson’s long-term reliability and application support.

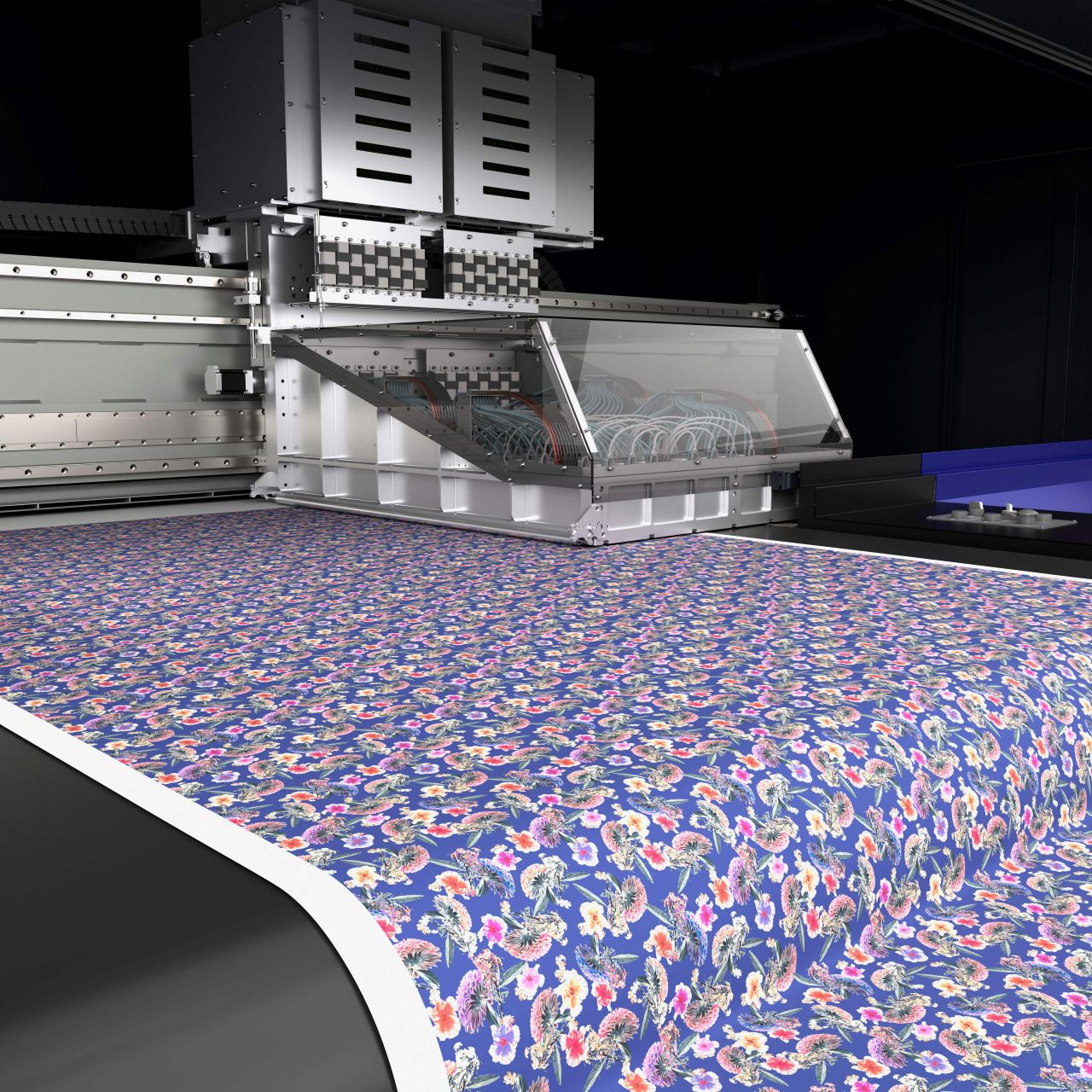

The ML-64000 is engineered for industrial-scale production while retaining the flexibility that digital technology offers. Capable of producing up to 10,000 linear metres per day at a 1.5-metre fabric width, it bridges the gap between conventional high-volume screen printing and agile, on-demand digital production. This installation demonstrates that digital printing is no longer confined to sampling or short runs—it is now a serious contender for mainstream industrial manufacturing.

Equally important is the sustainability dimension. Advanced pigment ink technology significantly reduces water usage, chemical consumption and process waste compared to traditional textile printing methods. As global brands intensify scrutiny around environmental performance, this installation signals India’s readiness to align with those expectations.

Redefining Scale, Speed and Consistency

For years, conventional printing technologies dominated high-volume production due to perceptions of speed and scale. Digital printing was seen as ideal for sampling or limited runs. According to Mr. Prabagaran, that perception is rapidly changing.

The ML-64000 demonstrates that digital printing can combine industrial productivity with operational flexibility. What differentiates Epson’s approach is its vertically integrated technology development. Epson designs and manufactures its printer hardware, PrecisionCore printheads, inks, ink delivery systems and software in-house. This end-to-end integration allows optimisation across every stage of the printing process, ensuring predictable colour consistency, repeatability and cost control.

For exporters facing shorter product life cycles and rapidly changing trends, the reduction in time from sampling to final production is transformative. Digital printing eliminates screen preparation, colour formulation storage and complex setup processes, allowing manufacturers to respond quickly to global demand while maintaining production reliability.

Meeting Stringent Export Market Requirements

Home décor exporters operate under stringent compliance and quality standards. Colour variation across repeat orders can damage brand relationships, while non-compliance with environmental and safety norms can block market access altogether.

The ML-64000’s pigment ink technology complies with internationally recognised certifications such as OEKO-TEX® Eco Passport, GOTS 7.0 and bluesign®. These certifications are increasingly mandatory for supplying to global home décor and lifestyle brands. Beyond certification, the ink system delivers rich colour depth, strong wash fastness and exceptional reproducibility.

One of the most critical requirements for exporters is repeatability. If an order is reproduced after six months, the colours must match precisely. Epson’s integrated colour management system ensures this consistency, allowing Indian manufacturers to build long-term trust with global buyers.

The Shift from Conventional to Digital Manufacturing

India’s textile printing landscape is evolving. Typical job sizes now range from 100 to 2,000 metres, reflecting growing demand for customised, smaller lot production. Conventional screen printing requires skilled labour for sampling, screen preparation and colour matching. It also demands maintaining screens and colour formulations throughout production, adding operational complexity and cost.

Digital textile printing simplifies this process. By removing many manual interventions and reducing setup time, it allows manufacturers to operate more flexibly and efficiently. Improvements in ink pricing have also brought down the cost per metre, making digital printing economically viable even in production environments.

Epson strengthens this transition by offering a complete ecosystem, including pre- and post-treatment chemicals, ensuring customers have a seamless pathway from conventional to digital manufacturing.

Beyond Speed: What Defines Competitiveness Today

In today’s global marketplace, print speed alone does not determine competitiveness. Manufacturers must demonstrate precise colour matching, consistent quality, strong fastness performance and strict compliance with safety standards.

Equally important is long-term partnership. Exporters expect technology providers to ensure high machine uptime, continuous application guidance and lifelong colour management support. Epson positions itself strongly in this area by combining technology reliability with ongoing service engagement.

Mr. Prabagaran emphasises that sustainable operational performance, rather than short-term gains, is the real differentiator in export-led growth.

The Role of Application Expertise and End-to-End Support

Successful digital adoption requires more than advanced hardware. Recognising a gap in application-level support in the Indian market, Epson established its Textile Solution Centre in Bengaluru.

The centre simulates real customer production environments by integrating printing systems with pre- and post-treatment equipment. This allows Epson’s team to optimise processes, refine applications and guide customers through implementation challenges before full-scale deployment.

The centre represents Epson’s evolution from a machine supplier to a solution partner. By investing in application research and real-time process validation, Epson enables customers to scale confidently.

Economics and Sustainability: A Dual Advantage

Digital printing with advanced pigment ink technology offers a compelling combination of environmental and economic benefits. Waterless printing significantly reduces environmental impact compared to conventional processes.

Because Epson controls its core technologies, it can optimise productivity, consistency and total cost of ownership. For manufacturers targeting export-led growth, this balance between sustainability and profitability is crucial. Scaling production while maintaining cost competitiveness and environmental compliance is no longer optional—it is essential.

A Growing Digital Future for India

India’s digital textile printing market is poised for strong growth. Government initiatives encouraging water conservation and sustainable manufacturing further support this transition.

As a frontrunner in pigment ink-based digital textile printing, Epson aims to drive this transformation through continuous innovation and strong application support. With digital adoption accelerating, particularly in home décor, Epson’s strategy is focused on enabling manufacturers to build future-ready, sustainable production capabilities.

Epson’s Journey in India

Epson entered India’s digital textile printing space in 2019 and has recorded approximately 35% CAGR growth year-on-year. Over time, the company has evolved from being perceived primarily as a technology provider to becoming a comprehensive solutions partner.

Its portfolio now spans Direct-to-Fabric systems such as the Monna Lisa series, Direct-to-Garment, Direct-to-Film and Dye Sublimation solutions. This breadth enables Epson to cater to manufacturers at every stage—from sampling and customised short runs to industrial-scale production.

The Textile Solution Centre further reinforces this comprehensive approach, supporting customers across application development, process optimisation and scalable implementation.

The installation of the Monna Lisa ML-64000 at Priya Darshani Designs is not just a technological milestone; it symbolises a broader industrial shift. Digital textile printing in India has matured from an experimental alternative to a robust, scalable production solution capable of meeting global standards.

As sustainability expectations intensify and export markets demand agility and precision, digital printing will increasingly define competitive advantage. Through integrated technology, application expertise and long-term partnership, Epson India is positioning itself at the forefront of this transformation.

The next phase of India’s textile growth story will not be written solely in terms of volume—it will be defined by efficiency, traceability, sustainability and technological excellence. In that journey, digital textile printing will play a central role.

Suggested Highlight Quotes

“Digital textile printing is no longer limited to sampling or short runs; it is now capable of delivering true industrial-scale production with consistent quality.”

“Our strength lies in designing and manufacturing every core printing technology in-house, enabling us to optimise quality, sustainability and cost of ownership for our customers.”