The global textile industry in 2025 finds itself navigating turbulent waters, with wars, tariffs, and disrupted trade flows reshaping long-standing dynamics. Yet, for ELiAR, a company with more than four decades of experience in textile automation and dyehouse solutions, these challenges have only reinforced its core strengths—innovation, adaptability, and partnership. As Ata Turgutalp, International Sales & Marketing Leader at ELiAR, explained: “Rather than being hindered by external turbulence, we have taken the opportunity to deepen our ties with customers, invest further in innovation, and support manufacturers as they adapt to rapidly changing conditions.”

For ELiAR, 2025 has been a year of consolidating fundamentals while embracing change. Despite global headwinds, the company has maintained robust performance by focusing on customer-centric innovation and long-term sustainability. Its approach has allowed dyehouses worldwide to achieve efficiency, consistency, and environmental responsibility—even in the face of volatile markets.

Innovation at the Core

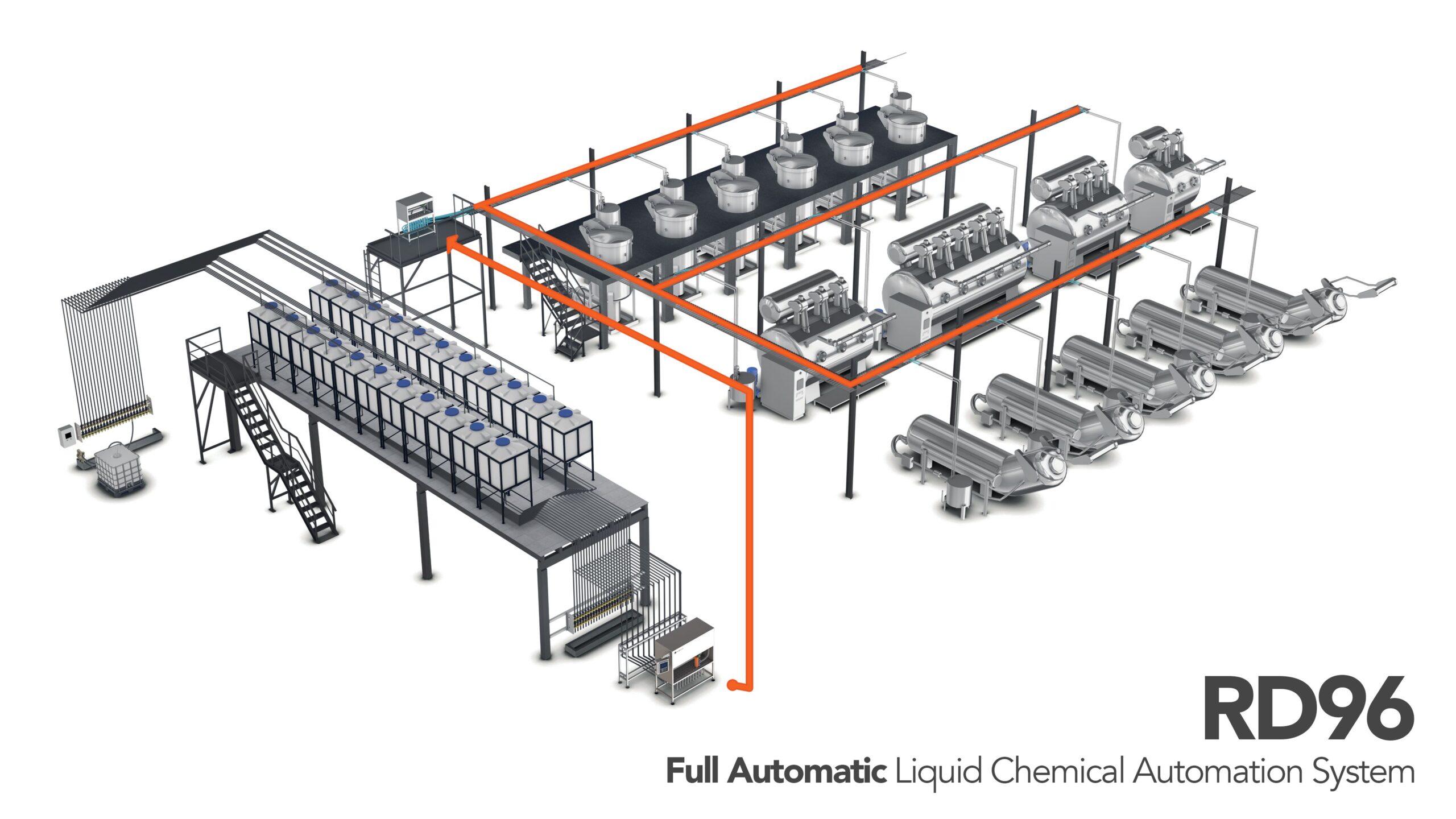

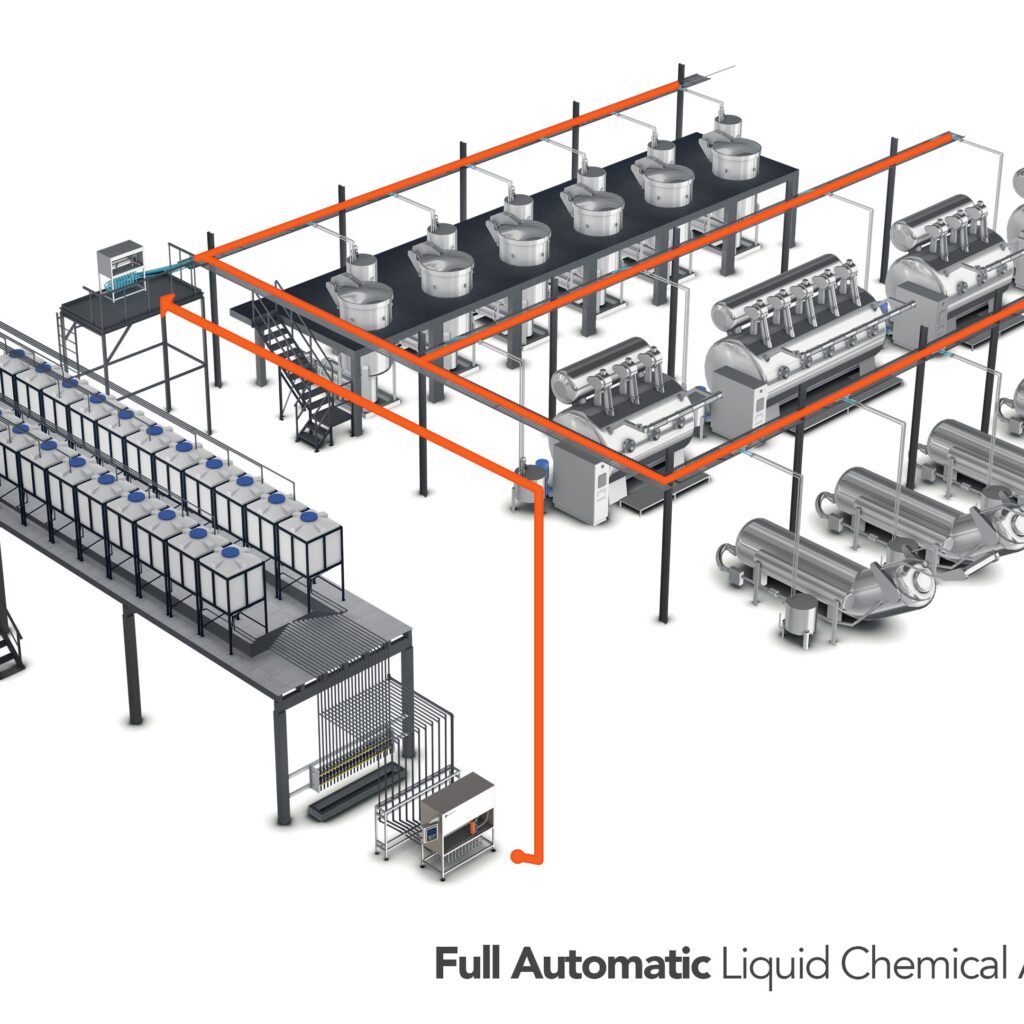

At the heart of ELiAR’s strategy lies an unwavering commitment to research and development. Innovation here is not restricted to machines or software; it is an integrated philosophy. One of ELiAR’s key advancements is its smart sensor portfolio, which measures parameters such as conductivity, colour absorbency, and dye bath behaviour with exceptional precision. When paired with the next-generation T9 series batch controllers and automation systems, these sensors empower dyehouses to achieve consistent “first-time-right” results, a critical factor in reducing waste and costs.

Equally transformative is ELiAR’s TELESKOP MES platform, which has evolved from a monitoring tool into a comprehensive digital factory solution. Incorporating AI-driven decision support, predictive maintenance, and sustainability dashboards, TELESKOP enables mills to move from reactive control to proactive optimisation—paving the way for smarter and more sustainable dyehouses.

Showcasing the Future at ITMA Asia 2025

At the much-anticipated ITMA Asia 2025 in Singapore, ELiAR will present its most advanced technologies at stand H8 C101. The exhibition will feature live demonstrations of how its mechatronics, control intelligence, and sustainability-driven design converge into one seamless ecosystem. Visitors can expect to see:

– Automation systems engineered to reduce chemical waste while maximising repeatability.

– Expanded smart sensor portfolio delivering unmatched measurement accuracy.

– AI-powered TELESKOP MES capabilities, redefining what digital dyehouse management looks like.

“Our vision is to show the industry how an integrated ELiAR ecosystem can transform a dyehouse into a digitally intelligent, resource-conscious, and future-ready operation,” said Mr. Turgutalp.

Growth Across Global Markets

Despite tariff disruptions, ELiAR has delivered solid growth in 2025, particularly in North Africa, South Asia, and South America. These regions are experiencing strong momentum, driven by sustainability regulations and rising labour costs that make automation essential. Looking ahead, ELiAR plans to consolidate its presence in these markets while investing further in South Asia, where demand for advanced automation is accelerating.

India: A Strategic Growth Engine

Among all global markets, India stands out as a cornerstone of ELiAR’s strategy. While U.S. tariffs have impacted exports, the long-term outlook remains positive. “The scale, dynamism, and entrepreneurial spirit of Indian textile manufacturers continue to create opportunities for advanced automation solutions,” Mr. Turgutalp affirmed.

ELiAR has recently partnered with leading Indian dyehouses, demonstrating how its systems directly address priorities of efficiency and sustainability. Beyond being a key customer base, India is seen as a strategic partner in shaping the next chapter of global textile manufacturing. Two major shifts are currently reshaping the Indian textile landscape: the transition to man-made fibres (MMF) and fresh

investments in dyeing and processing capacity. ELiAR is prepared to support both.

MMFs require greater precision in dyeing compared to cotton, making advanced dosing and control systems vital. At the same time, India’s capacity expansion projects present opportunities to build smart factories from the ground up. As Mr. Turgutalp highlighted: “Instead of retrofitting outdated infrastructure, Indian manufacturers now have the chance to leapfrog into digital, sustainable production. ELiAR is uniquely positioned to support this leap.”

The Digital Factory and Industry 4.0 Leadership

ELiAR has been pioneering automation and digitisation in tandem. Its dosing and batch controllers bring precision to physical processes, while TELESKOP MES captures and analyses real-time data across the factory floor. Recent innovations include AI-driven anomaly detection, predictive maintenance, and ERP integration for end-to-end traceability. Enhanced by digital twin technology, ELiAR’s “Digital Factory” creates a closed-loop ecosystem where sensor feedback, machine action, and operator input converge

seamlessly. “The outcome is a factory floor where decisions are not made by intuition alone, but guided by real-time intelligence,” Mr. Turgutalp said.

Sustainability: From Burden to Advantage

For ELiAR, sustainability is not an add-on but a guiding principle. Its #SustainTheFuture philosophy ensures every solution is designed to reduce energy, water, and chemical use while improving productivity.

“Sustainability is the new competitive advantage. Only those who deliver solutions that minimise resource consumption will remain relevant,” said Mr. Turgutalp. He emphasized that ELiAR sees sustainability not as a burden, but as an innovation pathway that creates long-term value for both customers and the environment.

Looking Ahead: Vision for Growth

As 2025 draws to a close, ELiAR remains confident about the textile industry’s long-term transformation. The pressures of rising wages, stricter environmental regulations, and shifting consumer preferences will only accelerate the need for intelligent automation.

“Our strategy is clear: to lead this transformation by innovating at the intersection of mechatronics, software, and sustainability. ELiAR’s vision is to become not just a provider of machinery, but the digital brain of the textile factory—empowering manufacturers to operate with precision, agility, and responsibility,” concluded Mr. Turgutalp.

ELiAR’s journey in 2025 reflects a company deeply rooted in resilience, yet boldly embracing the future. With its innovation-led portfolio, sustainability-first philosophy, and commitment to empowering global dyehouses, ELiAR is positioned as a pivotal player in shaping the future of textile manufacturing. As the

industry steps into a new era of digitalisation and responsibility, ELiAR stands ready to be its trusted partner, redefining what it means to sustain the future.