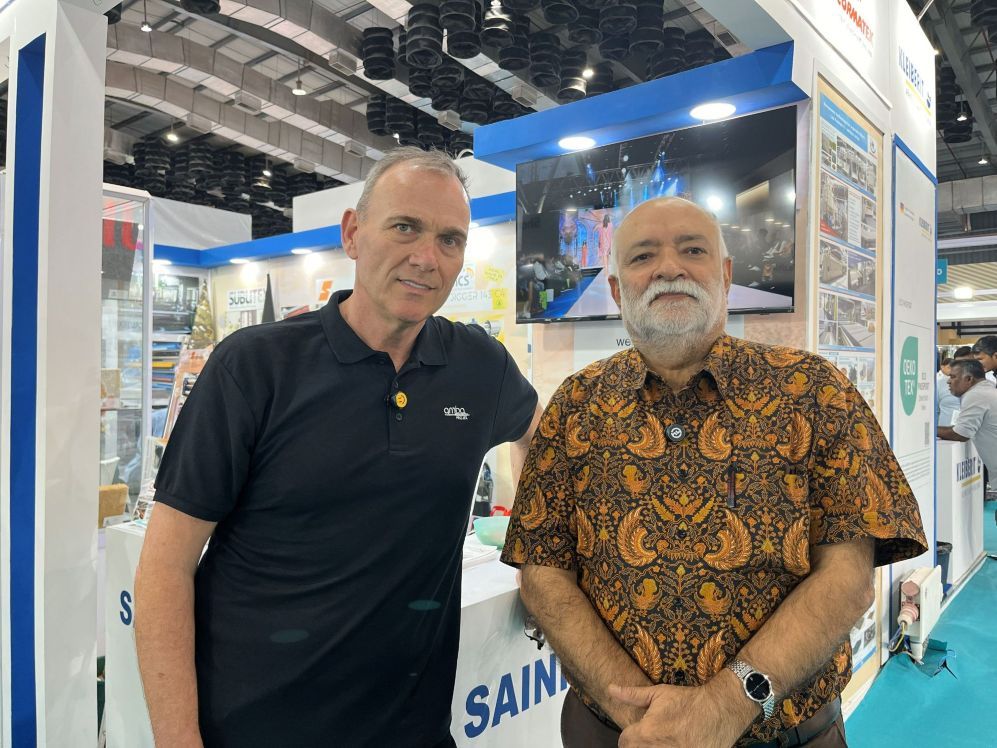

Exclusive Interview by K. Gopalakrishnan, Pics by Manikandan

India’s technical textiles industry is entering a transformative era marked by rapid innovation, expanding applications and rising global competitiveness. At the forefront of this evolution stand Amba Projex Ltd, a renowned UK-based specialist in coating and laminating technologies, and Sainit Exports, one of India’s most respected solution providers for technical textiles. In a conversation at Techtextil India, Mr. Barry Goodwin and Mr. Jayesh Nanavati reflected on their long-standing collaboration, the tremendous opportunities emerging in India and their shared mission to accelerate India’s technical textiles capability through technology, expertise and mentorship.

A Partnership Rooted in Technical Expertise and Market Understanding

Amba Projex has had a strong presence in India for more than three decades. Barry recalled his first visit in the early 1990s, noting how dramatically the market and exhibitions have transformed. “You look up and down the aisles in Mumbai today and you could be in any major city in Europe,” he said, emphasizing how India has matured into a global hub for technical textiles.

Sainit Exports, led by Jayesh Nanavati, brings an unmatched understanding of product design, application development and market needs. Their approach goes far beyond selling machines. “We work from raw material to finished product. We teach customers how to make money and how to choose the right product before anything else,” Jayesh explained. This philosophy has helped countless Indian manufacturers enter high-value technical textile segments with confidence.

Barry praised Jayesh’s influence in shaping the sector, stating, “I almost feel he is the godfather of the technical textile industry in India.” Their combined expertise offers customers not just technology but complete solutions, including product selection, reverse engineering, process design and long-term guidance.

Delivering End-to-End Technical Textile Solutions

Sainit Exports and Amba Projex differentiate themselves by delivering comprehensive, end-to-end project support. Customers receive guidance on:

• identifying niche products that offer strong margins

• understanding global market gaps and emerging opportunities

• selecting the right machinery and processes

• optimizing production for profitability and sustainability

Jayesh emphasized the importance of choosing the right product before investing in machinery. Many new entrants, he noted, make the mistake of purchasing equipment first and then searching for a product. “Please think twice,” he advised. “Select products that are not available in the Indian market yet. We can guide customers with full manufacturing processes, machinery requirements and technical details.”

This approach reflects their strong belief that India has the potential to become a global powerhouse in technical textiles as European and US manufacturers scale down operations. “The growth is phenomenal,” Jayesh said. “The sky is the limit.”

India’s Strategic Importance in Amba Projex’s Global Expansion

Amba Projex operates across five continents, including Australia, Korea, South America and Europe. Yet India remains a priority market due to its scale, dynamism and accelerating shift toward value-added textiles. “India has been on our radar for about twenty years,” Barry confirmed. “We see great potential here.”

As Vice Chairman of the British Textile Machinery Association (BTMA), Barry shared that many UK technical textile machine builders view India as the world’s most promising market for the next decade. The country’s rapid growth, expanding production base and appetite for advanced machinery are creating fertile ground for innovation and investment.

Empowering Indian Manufacturers to Climb the Value Chain

Both leaders see enormous opportunity for Indian mills to move from commodity production to value-added technical textiles. Barry advised manufacturers to build on what they already do well. “Whatever you are doing now, do it better by adding value. If you are weaving greige cloth that will be coated or laminated, invest in equipment and do it yourself.” This shift from outsourcing to in-house value addition can significantly improve margins and reduce dependency on external players.

Jayesh also stressed the importance of an incremental approach. Instead of heavy upfront investment in basic machinery, he recommends utilizing existing equipment, outsourcing select processes and gradually integrating backward operations. “A project should pay back in one to two years,” he said. “Otherwise it is not a viable technical textiles venture.”

Commitment to Sustainable Manufacturing

Sustainability forms a central pillar of both companies’ project philosophy. According to Jayesh, their recommended processes and machinery minimize water usage, reduce carbon emissions and deliver environmentally responsible products. India’s emerging technical textile players, he believes, must integrate sustainability from the beginning to remain competitive and compliant with global standards.

Amba Projex’s coating and laminating technologies also align strongly with sustainability goals by extending product life cycles, enabling lighter materials, reducing waste and supporting recyclable substrates.

A Vision for the Future: India as a Global Technical Textiles Powerhouse

Looking ahead, both Barry and Jayesh are confident that India is entering its most promising phase in technical textiles. A growing economy, rising domestic consumption, a skilled workforce and supportive government policies are laying a strong foundation for expansion.

Jayesh remains committed to mentoring new entrepreneurs and supporting the industry’s evolution through free consultation, technical training and honest guidance. “We can educate people at no cost,” he said. “We help them choose the right machinery, the right products and the right strategy.”

Barry echoed this optimism. “India is a hotbed for developing technical textiles now and in the future. The potential is extraordinary.”

Amba Projex and Sainit Exports continue to play a decisive role in shaping India’s technical textiles landscape. Through decades of experience, deep application knowledge and a partnership built on trust, the two companies are enabling Indian manufacturers to transition from low-margin commodities to high-value, globally competitive products. As demand for technical textiles accelerates worldwide, India stands poised for exponential growth, and leaders like Jayesh Nanavati and Barry Goodwin are guiding the industry into a new era of innovation, value creation and sustainable transformation.