At TITAS 2025, one booth that stood out both visually and conceptually was Xpore by BenQ Materials. With its butterfly-inspired design and the theme “Xpore e2cycle: From Electronic Waste to Performance Textiles,” the exhibit was a showcase of how Taiwan’s material-science leadership is driving sustainability across industries.

But behind the futuristic displays and seamless storytelling was a deeply technical journey — one that began not in textiles, but in electronics.

From Optical Films to Performance Textiles

BenQ Materials, long recognized as a global leader in display films, medical packaging, and battery materials, has now emerged as one of Taiwan’s most innovative players in sustainable performance textiles.

“BenQ Materials is a material company,” emphasized Rex KW Lee, Director of the Performance Textile Business Division, during our conversation at TITAS. “Our expertise is polymers — film, membrane, glue, and lamination. From this core, we expand into different industries: display, medical, advance battery materials for EV and now textile.”

This cross-industry expertise laid the foundation for Xpore, BenQ’s flagship performance textile brand, which combines nanoporous membrane technology with eco-conscious design.

The innovation originated from BenQ’s experience developing battery separator membranes — thin, durable, porous films used in lithium-ion batteries. “The CEO of BenQ Materials (ZC Chen) told me, ‘I have a membrane from separator — think about what it can be applied to,’” Rex recalled with a smile. That moment of creative challenge sparked years of R&D that re-engineered an industrial material into a breathable, waterproof membrane suitable for outerwear and active gear.

A Toxic-Free Future — PFAS-Free and Solvent-Free

At the heart of Xpore’s differentiation is its PFAS-free, solvent-free manufacturing process. Traditional waterproof-breathable membranes often rely on PTFE or fluorinated chemistries — materials now under scrutiny for their environmental persistence.

“We wanted PFAS-free. We wanted solvent-free,” said Rex, highlighting the company’s early commitment to eliminating harmful substances. Xpore’s membranes, based on polyolefin polymers (carbon and hydrogen), achieve high breathability without compromising durability or comfort. This makes them safer for both the planet and the people who produce and wear them.

The company’s sustainability philosophy runs deeper than product claims. “If you do not think from the beginning, it will be very hard to change in the end,” Rex explained. “Choose harmless materials. Choose the less energy-consuming process.”

That philosophy is visible across BenQ Materials’s manufacturing ecosystem — from its GRS-certified e2cycle process to bluesign® and OEKO-TEX® partnerships, and its internal drive toward RE100 and Carbon Net Zero by 2050.

Introducing e2cycle: Turning E-Waste into High-Performance Textiles

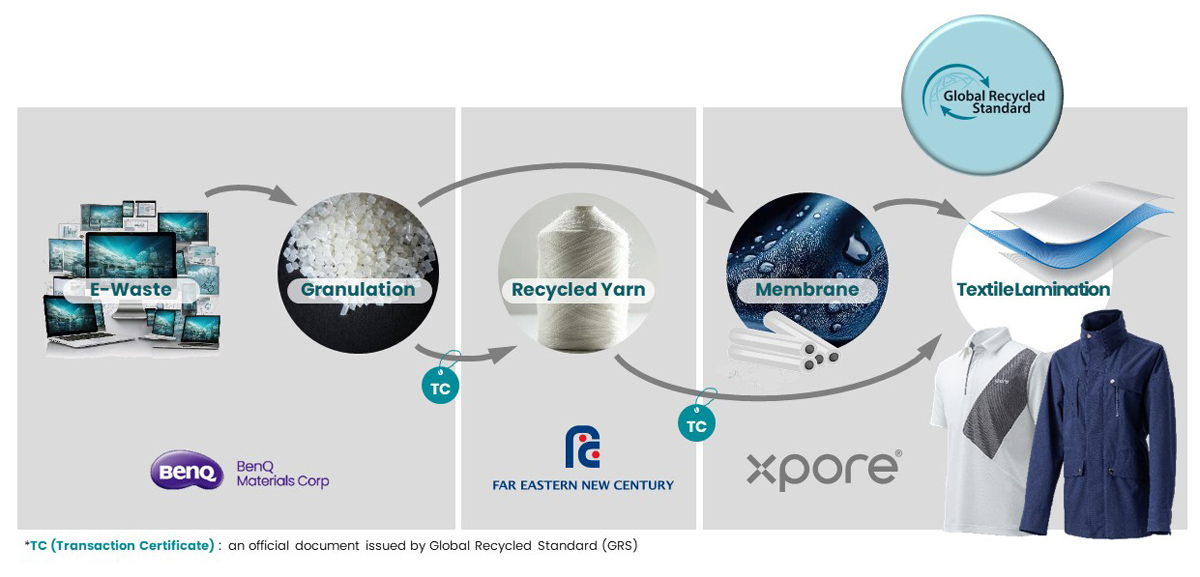

Xpore’s e2cycle technology — indivisually unveiled for the first time at TITAS 2025 — represents a world-first innovation: transforming discarded PET on LCD panels into recycled polyester textiles and membranes.

Through a traceable and clean mechanical recycling process, BenQ Materials extracts high-purity PET from electronic waste, repolymerizes it into granulation and integrates it into recycle yarns or performance membranes. The closed-loop process — electronic waste → PET pellets → yarns or → membranes → garments — is GRS-certified and reduces carbon emissions by up to 57% compared to virgin PET.

The company sources e-waste through Taiwan’s robust 4-in-1 Recycling Program, ensuring more than 90% PET purity, and integrates the output into sustainable yarns and membranes.

“The butterfly was our inspiration for e2cycle,” said Irene Chiang, Marketing Manager at BenQ Materials. “It symbolizes transformation and renewal — just as we turn what was once discarded into something functional, beautiful, and enduring.”

This innovation recently earned Xpore the Performance Days Eco Performance Award and recognition at ISPO Munich, cementing its position among the world’s most forward-looking performance textile brands.

Five Series, One Purpose — Redefining Functional Textiles

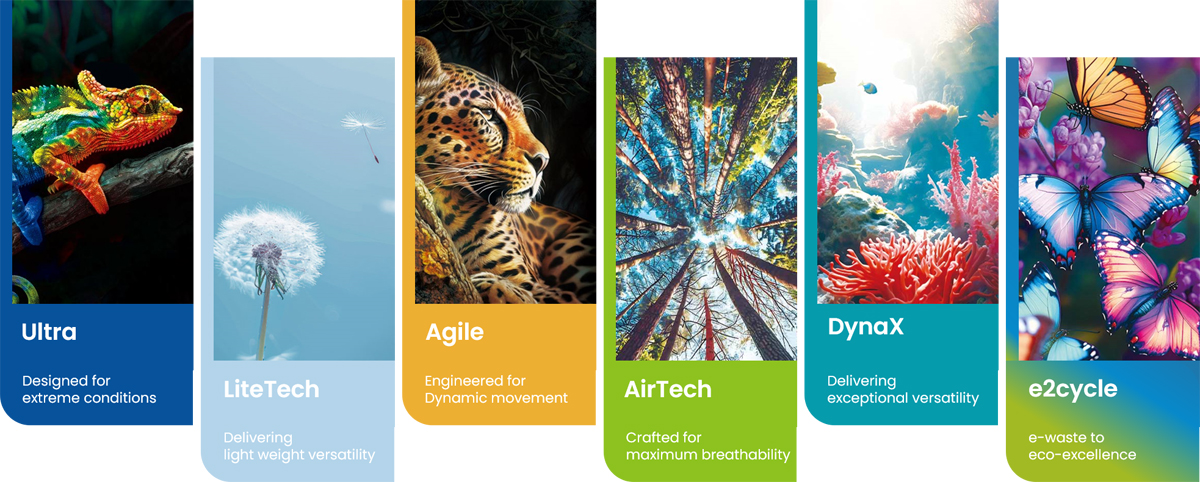

Alongside e2cycle, Xpore’s booth presented five specialized product lines, each inspired by nature’s design principles:

- Xpore Ultra – built for extreme conditions with waterproof ratings up to 30K.

- Xpore LiteTech – lightweight comfort with 15% less weight, ideal for insulation and outdoor wear.

- Xpore Agile – mono-material elasticity for dynamic movement and recyclability.

- Xpore AirTech – designed for tropical and high-humidity environments, offering ultra-breathability.

- Xpore DynaX – customizable balance of waterproofness, breathability, and weight to meet specific brand requirements.

Together, they embody the brand’s vision — “Nature’s brilliance, engineered into performance textiles.”

Beyond Innovation — Building Credibility Through Collaboration

BenQ Materials’s credibility in the sustainability space wasn’t built overnight — it was earned through rigorous brand partnerships and audits that tested every layer of its operations. A defining moment came when Patagonia, one of the world’s most respected outdoor brands, conducted a detailed supplier audit of BenQ Materials’s facilities before approving Xpore membranes for its products.

“Patagonia’s audit made me very impressed… they really do that,” Rex recalled. “They don’t just look at certifications or paperwork — they talk to people, from the engineers to the factory workers.”

The audit went far beyond typical environmental checks. Patagonia’s team examined energy usage, waste management, and chemical handling, but also interviewed line operators and reviewed wage and labor conditions to ensure fair practices were in place. Every department — from R&D and lamination to logistics — was asked to demonstrate transparency, traceability, and compliance with Patagonia’s strict social and environmental code of conduct.

Passing this assessment was a powerful validation for BenQ Materials. It confirmed that its sustainability claims were not just technological but systemic — built into the company’s culture of accountability and precision. As Rex put it, “That experience changed how we think internally. It’s not just about performance; it’s about people and responsibility.”

The Patagonia partnership also helped open doors to other global brands looking for reliable, PFAS-free membrane suppliers who could meet both performance and ethical benchmarks. For Xpore, it cemented a dual identity: a high-tech innovation born in Taiwan’s materials labs, and a responsible manufacturing platform trusted by the world’s most conscientious brands.

From Taiwan to the World — And an Opportunity for India

Taiwan’s textile ecosystem is known for high-value innovation, tight integration between materials science and manufacturing, and early adoption of sustainability standards. Through Xpore, BenQ Materials is extending that leadership into the global textile stage.

For India, the implications are particularly significant. The country’s growing emphasis on sustainable and functional textiles, backed by government programs like PLI schemes and “Make in India”, creates fertile ground for collaboration.

Rex sees clear potential. “India is an important market — but we always follow our brand customers,” he said. That means as international outdoor and sportswear brands expand sourcing and manufacturing in India, Xpore’s eco-innovations could seamlessly integrate into local supply chains.

By partnering with India’s performance fabric mills, garment exporters, and sustainability-focused brands, BenQ Materials could help Indian manufacturers leapfrog directly into PFAS-free, circular, and mono-material technologies — the very areas global buyers increasingly demand.

Conclusion: From Materials to Mission

Xpore’s debut at TITAS 2025 wasn’t just a brand showcase — it was a statement of intent. By transforming electronic waste into functional textiles and proving that sustainability and performance can coexist, BenQ Materials demonstrated how cross-industry innovation can redefine entire value chains.

As Rex summed up during our talk, “Don’t always stay in your comfort zone… think about what is most eco-friendly from the beginning.”

For India’s textile ecosystem — and for the world — Xpore offers both inspiration and a roadmap: proof that the path to a cleaner, smarter textile future lies in rethinking materials themselves.