Exclusive Interview by K. Gopalakrishnan

From a modest beginning in Panipat in the late 1990s to becoming one of India’s most respected and globally recognised manufacturers of nonwoven and polymer products, Park Industries has scripted a remarkable journey of innovation and leadership. Under the guidance of Mr. Pankaj Kapoor, Managing Director, the Park Group has grown into a diversified conglomerate with a strong national and international presence, supported by a wide portfolio of technical textiles and advanced polymer solutions. At Techtextil India, Mr. Kapoor offered valuable insights into the company’s evolution, its technology-led approach, and its uncompromising commitment to quality and sustainability.

A Journey Rooted in Vision and Expertise

Park Group was established in 1997 with its first manufacturing operations in Panipat. What began as a venture into NVH product manufacturing has expanded into a globally recognised organisation that includes Park Industries Pvt. Ltd., Park Nonwoven Pvt. Ltd., Park Felts Pvt. Ltd., and Essar Industries. Today, the Group operates over 20 plants across India and overseas, with major centres in Panipat, Chennai, Pune, Gujarat, Maharashtra, and Anantapur. It serves diverse industries such as textiles, automobiles, home furnishings, healthcare, heavy machinery, pharmaceuticals and more.

Mr. Kapoor, a veteran with more than four decades of experience in technical textiles, attributes the company’s success to its technical depth, innovative approach, and deep-rooted culture of operational discipline. His ability to combine industry vision with customer-centric innovation has been pivotal in shaping the organisation’s growth.

A Broad Portfolio with Expanding Global Reach

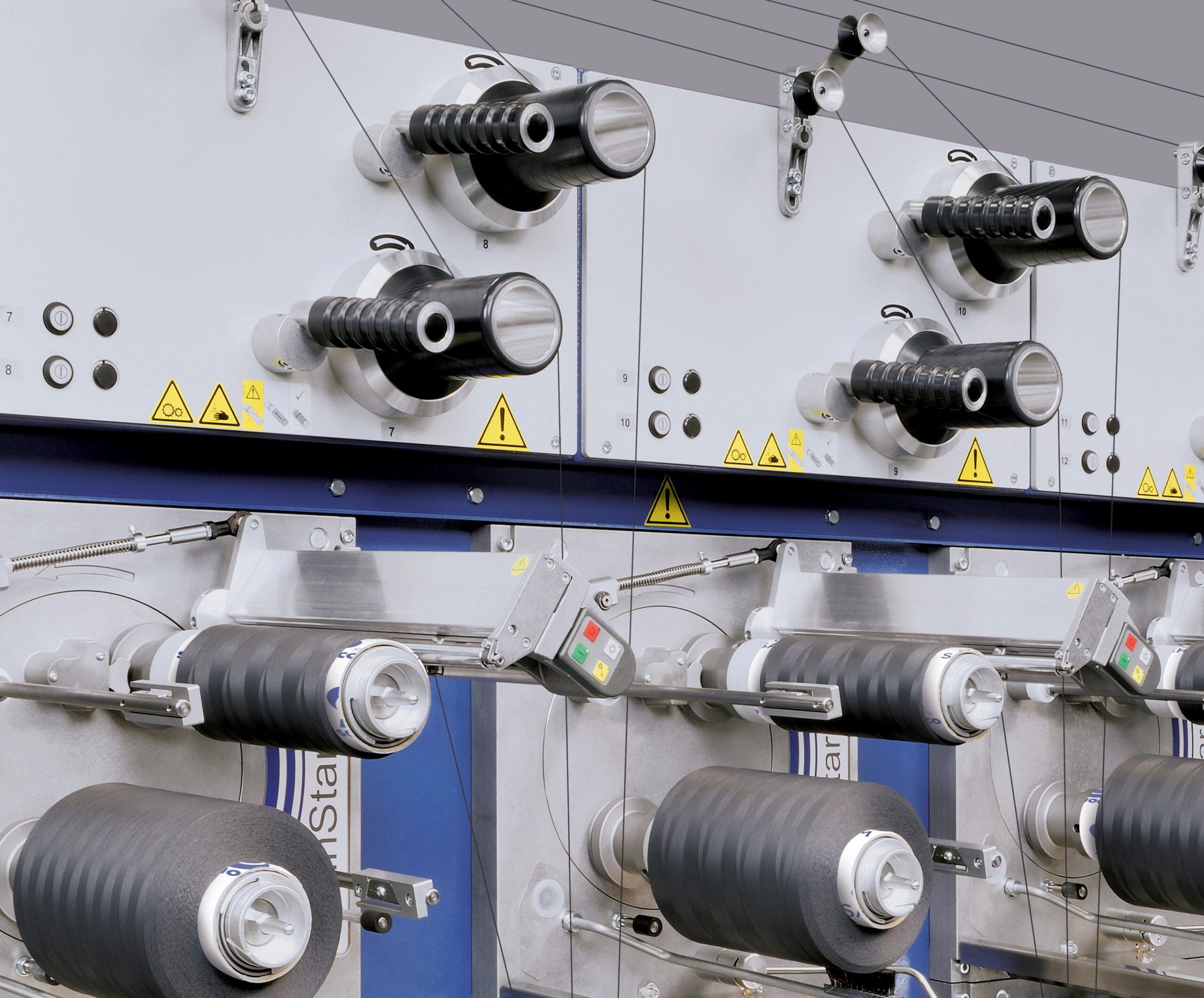

Over the years, Park Industries has developed an extensive product range powered by advanced nonwoven and polymer technologies. The company has expertise in felt production, needle punching, stitch bonding, thermo-bonding, compression moulding, lamination, EPP/PU foaming, and PP board extrusion. Its product portfolio includes dash insulators, floor carpets, bonnet and firewall insulators, roof pads, structured rib cord, velour fabrics, seat backs, EPP foam components, HVAC and cabin air filters, and moulded home furnishing items that it supplies to global retailers such as IKEA.

The company has also diversified into specialised defence components and railway applications and has expanded its export footprint to several international markets including Vietnam. Its PP wood boards and technical components have found acceptance among global players such as VinFast. The organisation’s capacity to innovate and co-develop products with customers has enabled it to make strong inroads into high-performance applications.

Scaling Infrastructure with Quality at the Core

Quality is central to Park’s operations. The company has steadily invested in a world-class manufacturing infrastructure, equipped with advanced production lines imported from leading global brands. Its plants include sophisticated laboratory testing facilities with instruments from Palas GmbH, Anton Paar, Mitutoyo and other leading global manufacturers.

The Group is also in the final stages of securing DSIR recognition for its central R&D facility in Gurgaon, which will significantly strengthen its research capabilities and allow third-party industry testing. With crores invested in testing and quality assurance, Park ensures that every product undergoes rigorous assessments of porosity, permeability, dust retention, thermal endurance, and high-temperature resistance.

Mr. Kapoor emphasises that quality is never negotiable. In his words, “If we make a commitment, we honour it—always. We may supply a lower quantity on some occasions, but we will never supply anything substandard.” This approach has not only earned the company the trust of customers but also won recognition such as the Daimler Global Quality Award for its superior headliner production supported by robotic CNC systems.

Sustainability and Circular Economy at the Forefront

Sustainability forms an integral part of Park’s operational philosophy. The company has adopted strong circular economy practices, ensuring that all internal waste is repurposed into useful products such as bags, baskets and moulded components. This reuse model not only reduces environmental impact but also instills a culture of responsibility among employees, resulting in lower waste generation.

Park Industries also ensures that its products are manufactured in an environmentally responsible manner, with several plants incorporating energy-efficient systems and recycling technologies. The organisation’s focus on sustainability aligns closely with global expectations and positions it strongly for long-term competitiveness.

Expansion into Geotextiles and New Materials

Park Industries is now preparing for its next phase of growth by entering the geotextiles and geosynthetics space. The company is setting up capacities for geomembranes, geogrids, geocells and geobags to serve the fast-growing infrastructure and environmental engineering sectors. It is also evaluating large-scale investments and is actively considering an IPO to support its expansion plans under various government incentive schemes.

Discussions with global automotive majors such as BMW indicate the growing global confidence in Park’s manufacturing capabilities. The company is cautiously evaluating overseas expansion opportunities, ensuring that its pace of growth remains aligned with its commitment to quality and operational control.

Recognitions and Leadership Beyond Business

Mr. Kapoor’s long-standing contribution to India’s textile and manufacturing landscape has earned him widespread respect. He has been honoured with several awards, including the prestigious Lifetime Achievement Award from the Indian Technical Textile Association (ITTA). Earlier, Park Industries received the Daimler Quality Award for its world-class automotive components. Beyond business, Mr. Kapoor has held leadership roles with ITTA, the Haryana Chamber of Commerce & Industry, CII, and Rotary International, reflecting his commitment to industry and community development.

A Vision Built on Innovation, Responsibility and Nation-Building

Park Group’s vision for the future is rooted in innovation, sustainability and people-centric growth. As Mr. Kapoor summarises, “Our group is committed to excellence—driven by innovation and grounded in the belief that growth must uplift our teams, our partners, and our country. Our mission is to bring material innovations to life, combining industrial expertise with sustainability, recycling and community impact.”

Park Industries stands as a testament to what Indian manufacturing can accomplish through vision, perseverance and an unwavering commitment to quality. From pioneering NVH products in the 1990s to becoming a global player in nonwovens, polymers and advanced technical textiles, the company has consistently delivered excellence. With its strong R&D capabilities, sustainability-driven operations, expanding product portfolio and visionary leadership, Park Industries is well-positioned to shape the future of India’s technical textiles and polymer industry. As global markets increasingly look to India for advanced materials, Park Group is not just ready for the future—it is helping lead the way.