KARL MAYER Technische Textilien is well on its way to become a system supplier to cater to its discerning customers complete and customizable solutions. KARL MAYER is currently working on comparing various production strategies for thermoplastic prepregs with unidirectional and multiaxial fibre orientation. Based on the company’s existing portfolio of UD 700, COP MAX 5 and SIM.PLY machines, its focus is trained on the respective resulting material properties, machine productivity and possible raw material uses.

Thermoplastic prepregs – Minimizing Weight

Thermoplastic prepregs are being increasingly utilized in the automotive industry to keep the weight low. If the unladen weight is low, more freight can be transported and fuel consumption would be less. Made from non-woven polymer and multiaxial non crimp fabrics, thermoplastic prepregs are being used for interior casing and thermal insulation of reefer containers, truck bodies, trailer superstructures and installations.

Given the great application potential of thermoplastic fibre composite materials, KARL MAYER is constantly developing its manufacturing process to offer innovations in this field.

SIM.PLY – Creating unidirectional fibre-reinforced tapes

SIM.PLY machine produces thermoplastic fibre-reinforced tapes and uses plastic in the form of films. It is part of an inline process where the fibres are spread and impregnated with the plastic film by applying pressure and increasing the temperature. Currently, SIM.PLY allows processing only for unidirectional fibre orientation where all the fibres in the manufactured semi-finished materials lie in the direction of production, producing unidirectional fibre-reinforced (UD) tapes. The innovative machine was launched at ITMA 2019, Barcelona.

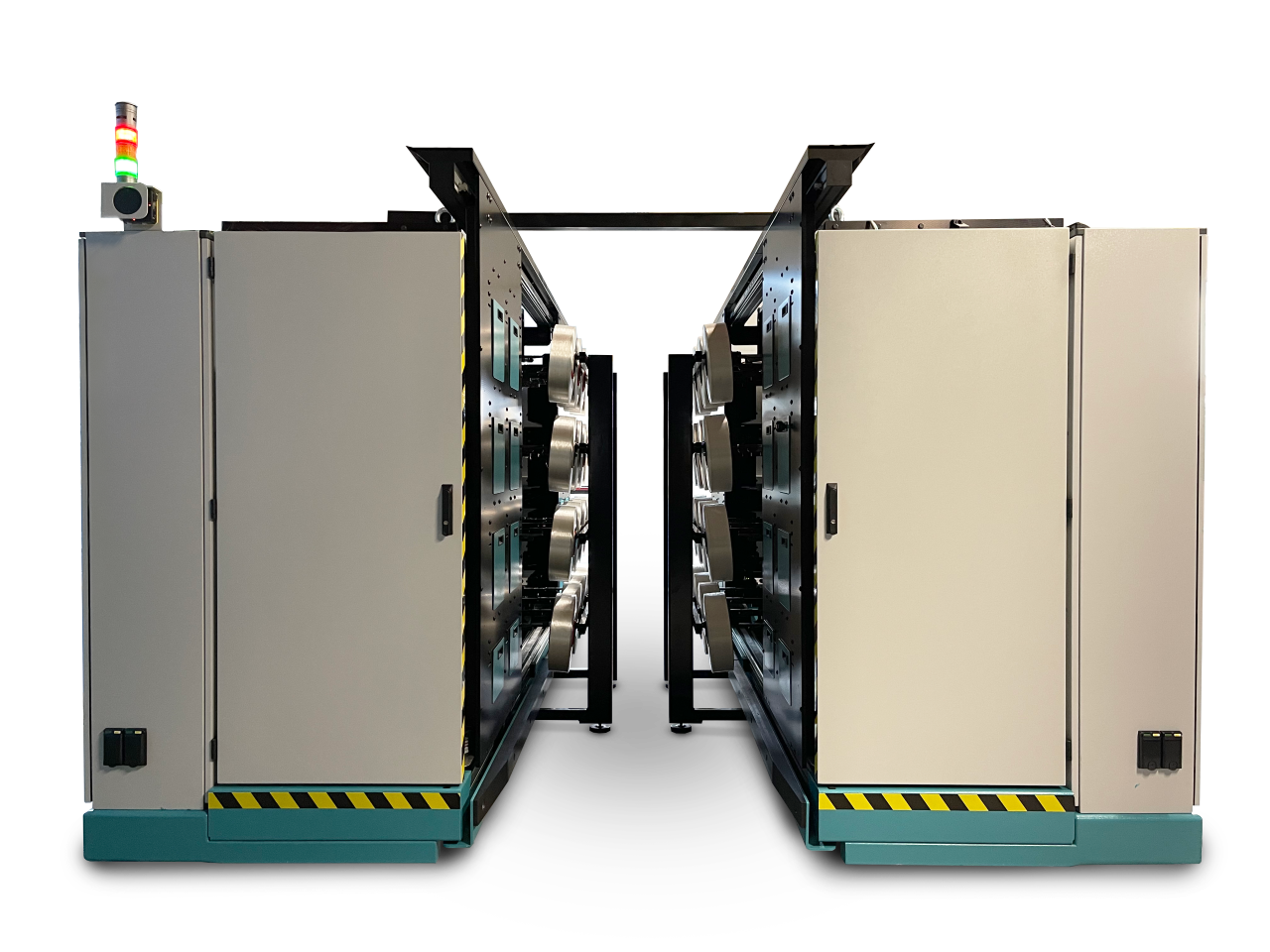

COP MAX 5 – Processing multidirectional fibre-reinforced structures

The COP MAX 5 multiaxial warp knitting machine can be used to produce reinforcing structures with flexible fibre orientations for thermoplastic prepregs. The multiaxial warp knitting machine is actually designed for using carbon fibres with finite weft insertion. The use of textile glass fibre is now being tested by KARL MAYER for the first time.

Nonwoven Polypropylene Impregnation

Another innovation by KARL MAYER is the polymer combination material for the composite solution using a nonwoven fabric rather than a polymer film. The company has investigated the suitability of these products as raw material for the plastic component in thermoplastic fibre composites. The nonwoven polymer consists of a polypropylene (PP) hot-melt nonwoven with low melt viscosities, produced using the meltblown procedure. The nonwoven fabric is easy flowing when melted and the individual glass fibres are well embedded. In general, nonwoven polymers offer advantages over their closed film counterparts due to their good air permeability, since the air can escape better from the fibre-plastic composite to be produced.

Stitch-bonding and Impregnation

The PP nonwoven fabric for this project work had an area weight of about 45 g/m². The fibre material was fed into the COP MAX 5 as a layer above and below an intermediate layer of spread glass with a fibre orientation of 45° or 60° angles. The individual layers of the sandwich structure were then stitch-bonded. When choosing the right warp knitting yarn, using a classic polyester variant is favourable because polyester yarn has a higher melting point than the PP hot-melt nonwoven fabric. This means it can withstand the subsequent impregnation process, thus ensuring the fibres are fixed permanently. The angular positions are not shifted while passing through the impregnation section. Initial investigations completed by the project partner in the field of nonwoven production have yielded positive results.