Groz-Beckert, a global leader in industrial machine needles, precision components, and textile system solutions, will participate at Techtextil India 2025 from November 19–21, 2025, at the Bombay Exhibition Center, Hall 4, Booth E31, Mumbai. The company will showcase innovations across four key product areas: Nonwovens, Weaving, Warp Knitting, and Sewing, with a dedicated focus on technical textiles and high-performance material processing..

Nonwovens: Advanced Felting and Carding for Technical Performance

At Techtextil India, Groz-Beckert will highlight its wear-optimized solutions for nonwoven production, designed to increase process stability, improve material consistency, and reduce operational downtime.

Key technologies on display include:

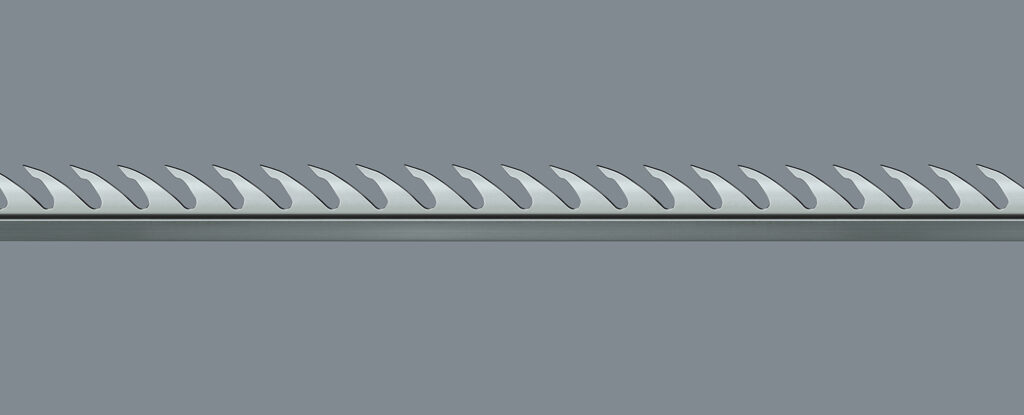

- Felting Needles with Enhanced Barb Geometry

Optimized for abrasive and mineral fiber blends, the latest barb designs ensure:

o Reduced needle wear

o Lower clogging tendency in materials like bentonite

o More uniform surface appearance at high throughput rates - InLine Card Clothing Solutions

Featuring SiroLockTM plus worker and doffer wires:

o Improved fiber control and web uniformity

o Extended service life and maintenance intervals

o Higher and reproducible carding quality across production runs

These solutions support demanding sectors such as automotive interiors, geotextiles, filtration, hygiene, and insulation materials.

Weaving: Precision Accessories and Efficient Warp Preparation

Groz-Beckert will also present its weaving preparation systems and high-precision accessories, engineered to enhance quality and machine productivity in both apparel and technical textile weaving.

Exhibit highlights include:

- Heald Frames, Healds, Drop Wires, and Warp Stop Motions

Designed for durability, consistency, and compatibility across major weaving machine

platforms. - High-Performance Reeds

Delivering precise thread guidance for:

o High-speed weaving

o Fine filament fabrics

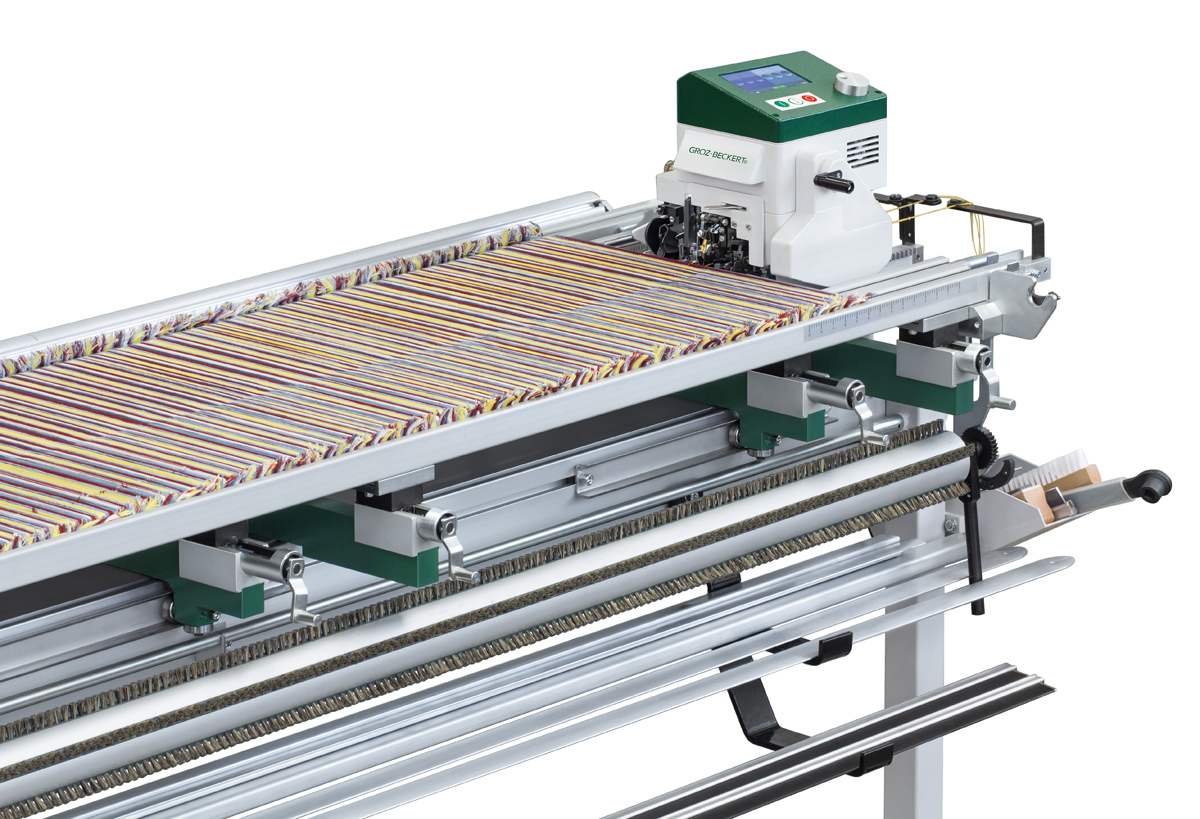

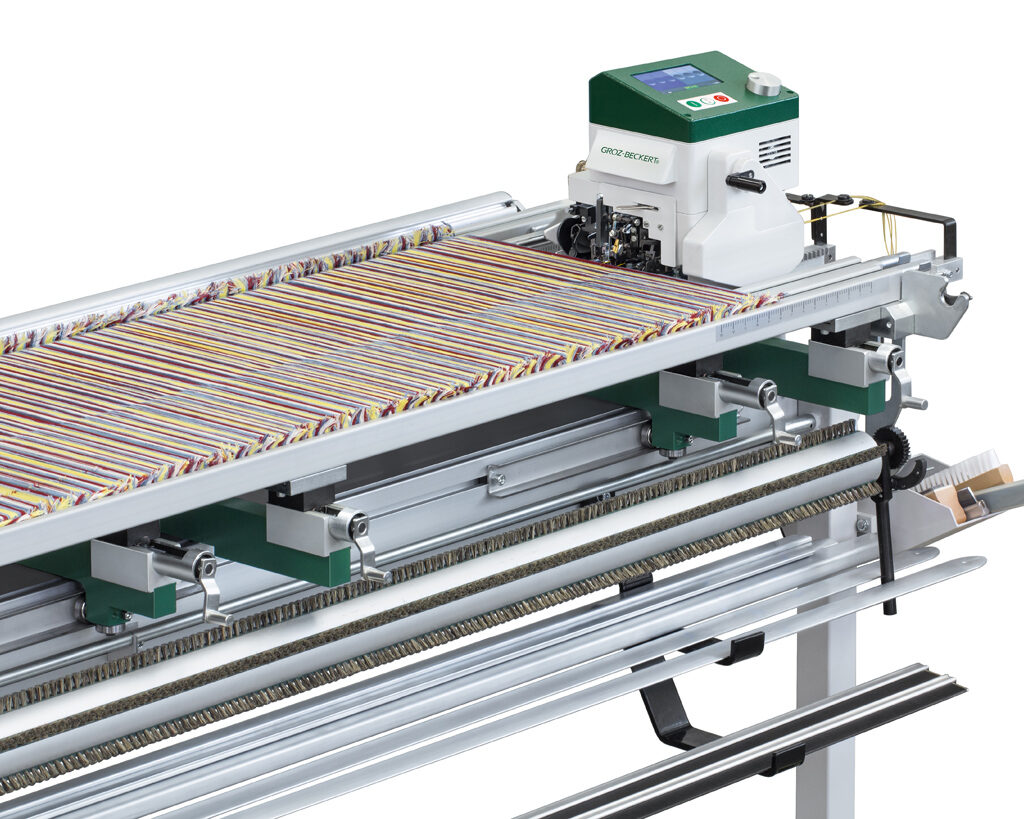

o Complex multi-layer and technical textiles - KnotMaster Warp Tying Machine

Featuring:

o Intuitive touchscreen operation

o Automatic knotting adjustment

o Support for diverse yarn types from cotton and polyester to aramid and

glass fibers

This ensures efficient warp changeovers, minimized downtime, and improved mill productivity.

Warp Knitting: Stability, Precision, and Module Integration

For the warp knitting sector, Groz-Beckert will showcase its ongoing developments in loop formation components for high-performance textile applications.

Highlights include:

- Guide Needles and Module Systems for net, mesh, spacer, automotive, footwear,

base fabric, and medical textile production - New Guide Needle Solutions for Piezo-Jacquard Machines, providing:

o Enhanced bending resistance

o Precise loop formation

o Longer component lifespan under dynamic load

These components support manufacturers aiming for consistent fabric geometry,

repeatability, and high-speed efficiency.

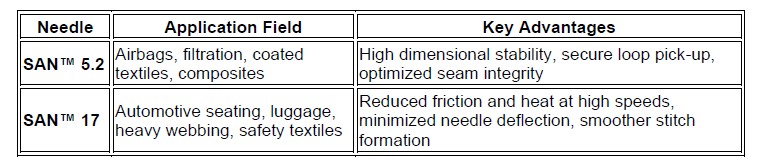

Sewing: Focus on SANTM 5.2 and SANTM 17 for Technical Materials

The Sewing Division will spotlight two specialized SANTM (Special Application Needles) designed for technical textile processing:

Commitment to the Indian Textile Ecosystem

With a strong network of local technical service experts, sales offices, and warehousing

across India, Groz-Beckert continues to support Indian textile manufacturers with application

knowledge, process consulting, and lifecycle support.