In today’s rapidly transforming textile landscape, automation, precision, and sustainability have become the cornerstones of innovation. As textile mills in India continue to embrace digitalization and efficiency, advanced technologies are driving a new era of productivity and quality control. After presenting COLOR DYEING and SMP at ITMA ASIA + CITME 2025 in Singapore, Color Service will showcase these new solutions at TECHTEXTIL INDIA 2025, taking place in Mumbai from November 19 to 21.

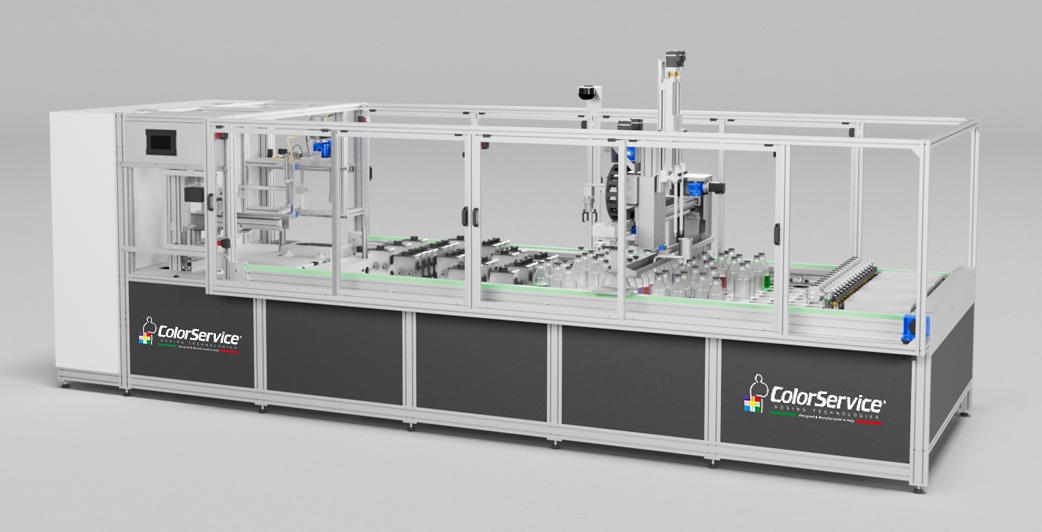

SMP is a fully automated system for preparing and dispensing dyes and chemicals solutions with unmatched precision and repeatability. The system has an independent dissolver capable of creating perfect dye solutions with concentrations up to 80 g/l, ensuring optimal dissolution, even for challenging dye powders.

The system allows for continuous operation, preparing fresh solutions while simultaneously pipetting into dyeing vessels. This parallel functionality saves valuable time and increases lab throughput. Solutions are automatically checked for freshness, even overnight, so there’s no need for manual supervision. One of SMP’s standout features is its self-cleaning bottles. Automatic washing cycles eliminate contamination and preserve solution purity, ensuring reliable and repeatable dyeing results every time.

The system also enables automatic chemical addition, such as acids or dispersing agents, with high accuracy, completely removing the need for manual dosing. SMP combines advanced automation with user-friendly design, making it an essential tool for laboratories that require consistent, clean, and high-quality solutions for dyeing processes.

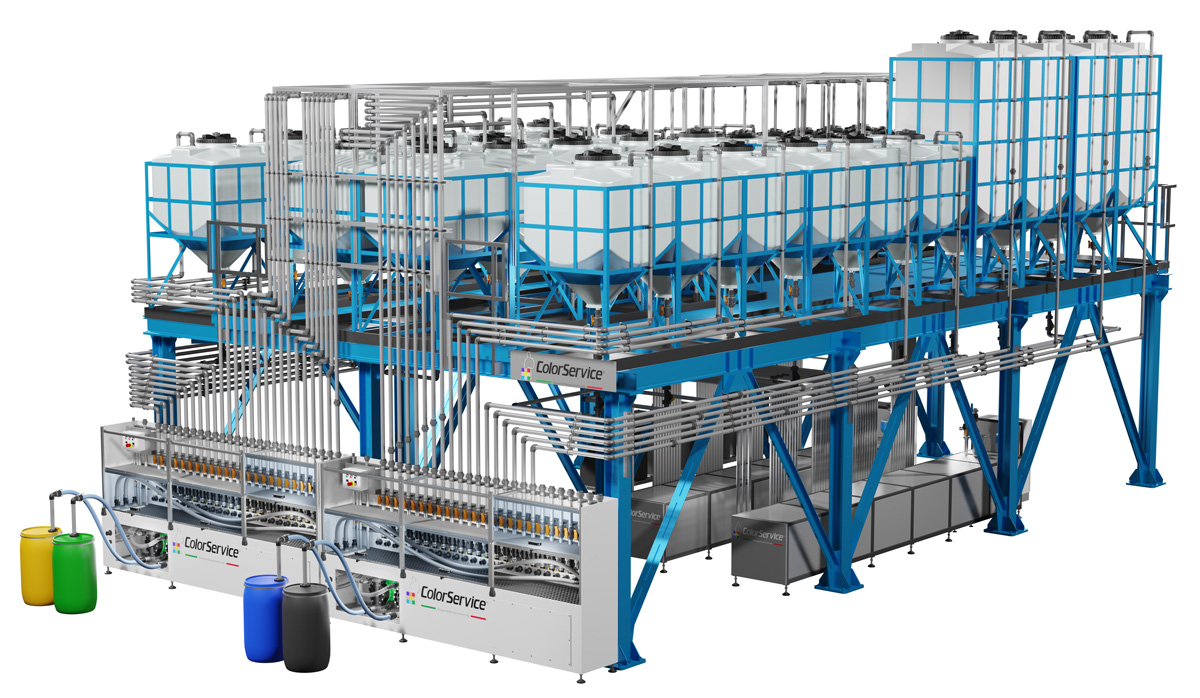

COLOR DYEING is an innovative modular system designed for high-precision dyeing in lab environments. It supports both high and low temperature dyeing, making it ideal for natural, synthetic, or blended fibres. The system operates in modular groups dyeing units, offering excellent flexibility and scalability. Each unit functions independently, with its own thermal insulation, safety thermostat, and autonomous dyeing cycle. This means multiple dyeings can be run in parallel, each with its own parameters, without interference.

The system handles dyebath volumes from 200 cc to 600 cc, and reaches a maximum temperature of 135°C, allowing for a wide range of dyeing conditions. Fast and uniform heating and cooling are guaranteed by the automatic indirect water-cooling system, controlled by an integrated solenoid valve.

Inside each unit, the material holder basket is made of AISI 316 stainless steel and features a magnetic drive rotation system, eliminating mechanical seals. This ensures both longevity and ease of maintenance while maintaining optimal agitation during dyeing.

“Explore our latest innovations, sustainable solutions and height performance machines designed to inspire your next big idea. Let’s shape the future of textiles together, meet us at Hall 4 – Booth E63” says Victor Macovei, Area Sales Manager at Color Service.