Salvade srl Italy is one of the best producer of the sublimation transfer printing machines . They are working in more then 50 countries. Sublimation transfer printing is a heat-based digital printing process that transfers dye from printed paper onto synthetic fabrics, primarily polyester or polymer-coated substrates. It is an eco-friendly, high-resolution method producing permanent, vibrant prints without affecting the fabric’s breathability or softness. This technique is widely used in sportswear, fashion apparel, home furnishings, and technical textiles requiring durable and photographic-quality prints.

Principle of Sublimation Transfer Printing

The process relies on the sublimation of disperse dyes, which directly transition from solid to gaseous state under heat and pressure. At 180–210°C, dye vapors penetrate polyester polymer chains, permanently embedding within the fiber matrix. This results in high wash, light, and rub fastness.

Chemical Principle:

• Dye Type: Disperse Dyes (Sublimation Grade)

• Temperature: 180–210°C

• Pressure: 3–5 bar

• Time: 30–60 seconds

Process Flow of Sublimation Transfer Printing

1. Digital Design Preparation – Artwork creation, color profiling, and mirroring.

2. Printing on Transfer Paper – Sublimation inks are printed on coated paper using inkjet printers.

3. Heat Transfer – Printed paper and fabric pass through a heat press or calender under heat and pressure.

4. Cooling & Separation – Paper and fabric are separated immediately after transfer.

5. Finishing – Brushing, calendaring, or compacting to enhance surface feel.

Equipment Used

The key equipment in sublimation transfer printing includes:

• Digital Inkjet Printer – For printing sublimation inks on coated transfer paper.

• Sublimation Transfer Paper – Acts as the dye carrier.

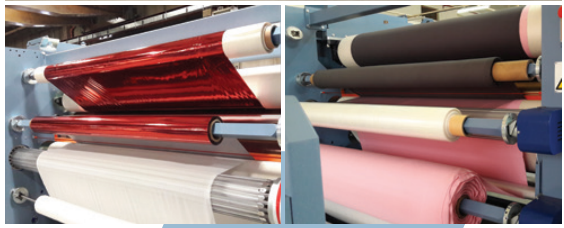

• Salvade Calender Machine – A rotary heat transfer machine used for continuous roll-to-roll sublimation transfer.

• Fume Extraction System – To remove vaporized dyes during sublimation.

• Fabric Winding/Unwinding System – For smooth continuous operation.

Salvade Calender Machine Description

The Salvade Calender Machine is designed for high-speed sublimation transfer on polyester and blended fabrics. It ensures uniform heat distribution, precise temperature control, and consistent pressure across the width of the fabric, ensuring sharp and vibrant transfer prints. The machine operates on a continuous roll-to-roll system, suitable for mass production.

Key Features:

• Drum diameter: 420–1000 mm (depending on model)

• Heating system: Oil-heated drum with digital temperature control (up to 220°C)

• Speed: 1.5–6 meters/minute

• Pressure: Pneumatic or hydraulic adjustable system

• Cooling roller for stable fabric exit

• Safety interlocks and fabric alignment control

• Optional automatic paper and fabric tension control

Suitable Substrates

| Substrate Type | Composition | Suitability |

| Woven Polyester | 100% Polyester | Excellent |

| Knitted Polyester | 100% Polyester | Excellent |

| Polyester Blends | ≥ 70% Polyester | Good |

| Nylon | Polyamide | Moderate (needs coating) |

| Cotton, Wool, Silk | Natural Fibers | Not Suitable |

Advantages and Limitations

Advantages:

• High color brilliance and sharpness.

• Excellent wash, light, and rub fastness.

• No water usage – eco-friendly process.

• Soft hand feel and breathable finish.

• Suitable for customized or short-run production.

Limitations:

• Only suitable for polyester or polymer-coated substrates.

• Requires precise temperature and pressure control.

• Not ideal for dark-colored fabrics.

Applications

• Sportswear and activewear (jerseys, cycling suits, leggings)

• Fashion apparel (scarves, dresses, shirts)

• Home furnishings (curtains, cushions, upholstery)

• Flags, banners, and soft signage

• Technical and automotive textiles (interior panels, linings)

Environmental and Economic Aspects

Sublimation transfer printing is a sustainable coloration process with minimal environmental impact. It eliminates water consumption and effluent generation typical of conventional dyeing. Transfer paper can be recycled, and energy usage is limited to the heating phase. The process supports on-demand, low-inventory production models, aligning with sustainable textile manufacturing.

Sublimation transfer printing using Salvade Calender Machine offers a reliable, efficient, and sustainable solution for producing high-quality printed polyester fabrics. It combines digital flexibility with excellent print durability and aesthetic performance, making it a preferred technology for technical, sportswear, and fashion applications.