Indorama Ventures, is one of the world’s leading petrochemicals producers, with a global manufacturing footprint across Africa, the Asia-Pacific, Europe and the Americas. Our portfolio comprises Integrated PET, Integrated Oxides and Derivatives, Fibers, Packaging and Specialty Chemicals. Indorama Ventures products serve major FMCG and automotive sectors, i.e., beverages, hygiene, personal care, tires and safety segments. Indorama Ventures has over 24,000 employees worldwide and consolidated revenue of US$10.6 billion in 2020. The group has recently announced investment and expansion plans in India, Russia and other global markets.

Investment in India

Indo Rama Synthetics (India) Limited (IRSL), the Indian subsidiary, will spend up to INR 6 billion (USD 82M) upgrading equipment and adding capacity at its manufacturing site in Nagpur, India. The capital expenditure plan includes a new PET resin manufacturing facility, additional balancing equipment, and a large range of specialty yarns, further strengthening IRSL’s ability to serve clients across the country.

India is a strategic market for IVL, where the company operates all three of its global integrated business segments – Combine PET, Fibers, and Integrated Oxides and Derivatives (IOD). IVL has continually developed its PET resin business in India since 2016 through IVL Dhunseri Petrochem Industries Private Limited (IDPIPL), a joint venture with Dhunseri Ventures Limited.

The new PET resin facility at Nagpur will add 700 tons of capacity per day and is expected to be operational by the second quarter of 2022. Together with plants at Haldia and Karnal, the Nagpur facility further strengthens IVL’s position as India’s largest resin producer, with a total capacity of over 1 million tons annually. With three manufacturing locations across the country, IVL serves customers throughout India.

The plant at Nagpur, which IVL has managed since 2019, is also the company’s first fiber manufacturing site in India, offering a wide range of staple fibers and filament yarns. Under the investment plan, it will meet global brands’ increasing demand for more high-quality and sustainable textile products.

Russian facility

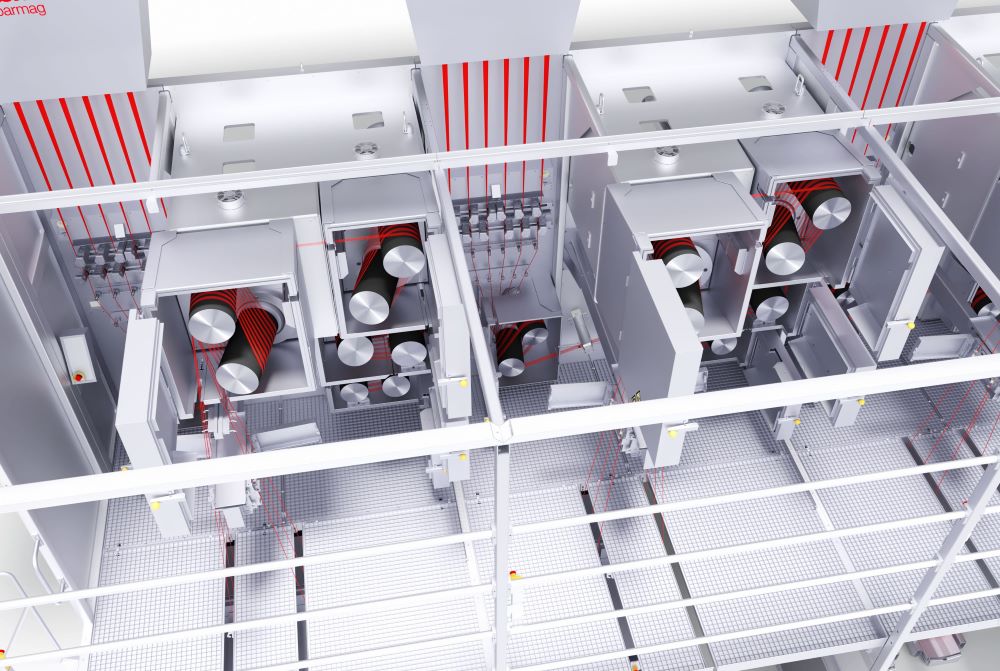

Avgol, an Indorama Ventures Limited company, a global leader in the manufacture of high performance non-woven fabric solutions, has announced it is investing in a new high-speed, high-capacity flexible multiple beam production line at its facility in Uzlovaya, Russia.

“The addition of this new line enables us to have greater production capacity for growing regional markets and support the release of new Avgol technologies,” said Tommi Bjornman, CEO of Avgol.

“Serving the growing baby diaper, adult incontinence and feminine hygiene markets along with satisfying sustained demand for meltblown filtration and medical materials, this investment enables Avgol to deliver an improved degree of service across the entire area while consolidating and strengthening our existing position,” he said.

Avgol, leads the global hygiene market with the most comprehensive range of ultra-lightweight spun-melt nonwoven fabrics. This new line at the company’s Uzlovaya facility, in the Tula Oblast region of Russia, will see Avgol investing in new Reicofil 5 (RF5) technology. The third line for this location will include biocomponent and corresponding high-loft capabilities thus producing materials for applications that meet the needs of upper tier products for Hygiene customers.

As part of the investment, Avgol is including new capacity for meltblown production with a dedicated line, ensuring a continuous supply of this critical material for the region.

One other aspect of the investment, and a new inhouse capability for Avgol, includes the addition of cutting-edge lamination capabilities. These capabilities will allow Avgol to offer enhanced performance products into the existing markets the company serves, as well as allowing the company to explore new opportunities in other markets.

“The RF5 line, meltblown line and lamination capabilities will provide us a powerful set of platforms as a base from which to provide high-value products for our customers,” said Mr. Bjornman. “It will enable us to further diversify the Avgol innovation portfolio while remaining true to our roots.”

Mr. Bjornman further commented that the investment will also significantly support further sustainable product development in Avgol, under its innovative FIT™ (Forward Innovative Thinking) strategy. “Avgol is committed to the future of nonwoven fabrics with a particular focus on bringing polyolefins forward as viable resins in single use articles,” he said.

“We are excited to bring new assets, new capabilities, and new technologies that will challenge customer expectations of the nonwoven fabric industry.”

This investment will move the Russian production facility to the second largest site for Avgol (the largest facility remains the Mocksville site in North Carolina, USA).

India is a strategic high-growth market for us. Our capital expenditure plan reflects our long-term commitment to the industry’s development in India. It is important that we continually invest to ensure that we can serve our customers across India, wherever we are needed.

– D K Agarwal, CEO of Combined PET, IOD and Fibers Business at Indorama Ventures